TM 5-805-4/AFJMAN 32-1090

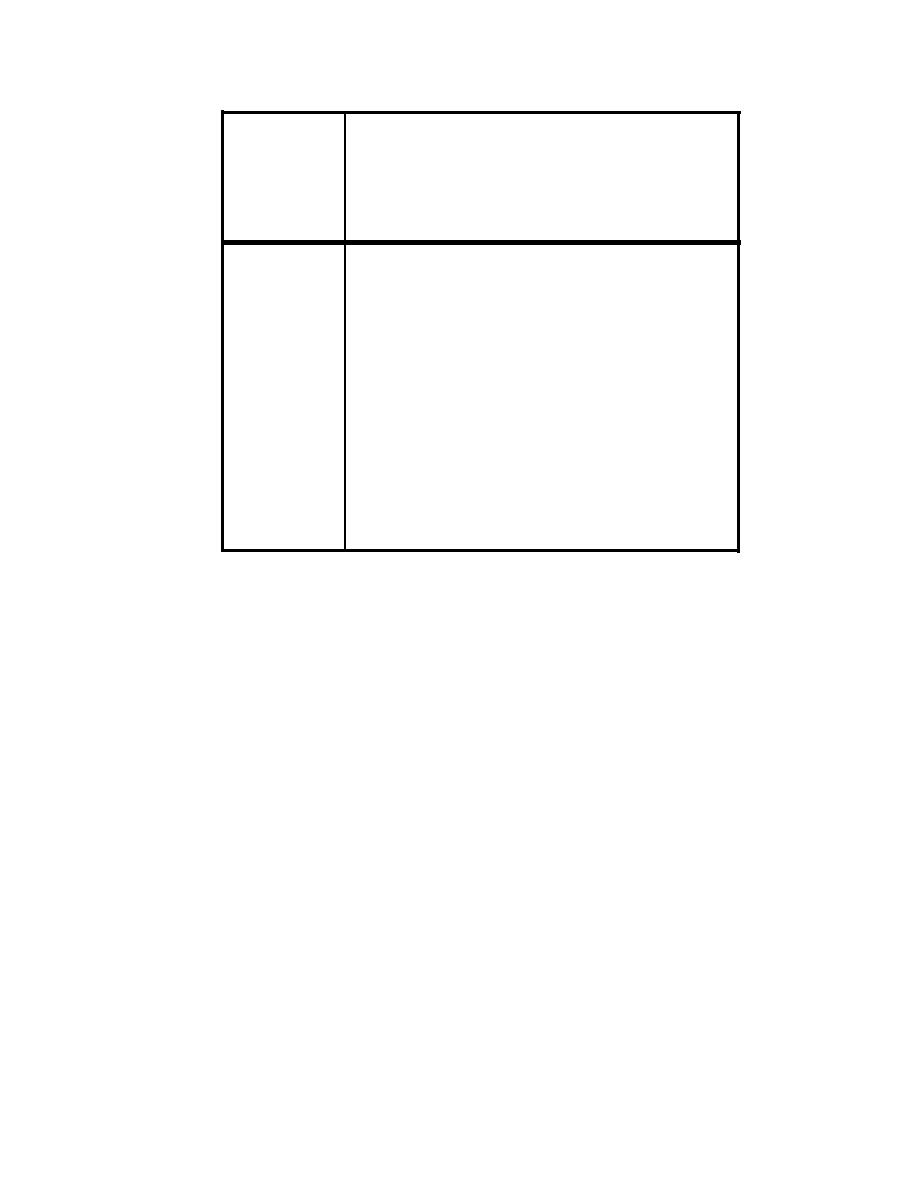

Table 4-7. Transmission Loss (in dB) of Plywood, Lumber, and Simple Wood Doors.

Thickness of Plywood or Lumber (in.)

2

4

Octave

1/4

1/2

1

Approximate Surface Weight (lb/ft.2)

Band

8

16

(Hz)

1

2

4

12

17

31

0

2

7

17

18

63

2

7

12

18

19

125

7

12

17

19

22

12

17

18

250

22

30

500

17

18

19

30

35

1000

18

19

22

35

39

2000

19

22

30

43

4000

22

30

35

39

43

47

8000

30

35

39

28

33

STC

18

21

24

Notes:

Surface weight based on 48 lb/ft.3 density, or 4 lb/ft.2 per in. thickness.

1.

2. Lumber construction requires tongue-and-groove Joints, overlapping joints,

or sealing of joints against air leakage. For intermediate thicknesses,

interpolate between thicknesses given in table.

3. For ungasketed hollow-core flush-mounted wood doors, use TL for l/h-in.

thick plywood.

4. For solid-core wood doors or approximately 2-in. thickness, well gasketed

all around, use TL for 2-in. thick plywood.

5. For small-area doors or boxes, framing around Cage of panel adds effec-

tive mass and stiffness and will probably give higher TL values than shown.

(a) Support of floating floor. The floating

can be added to any one of the Type 1 through 4

combinations. This becomes necessary when all

concrete floor should be supported off the structure

o t h e r floor systems clearly fail to meet the

floor at a height of at least 2 inches with properly

required TL values. The values given in table

spaced blocks of compressed glass fiber or multiple

4-16 are improvements in TL that can be added

layers of ribbed or waffle-pattern neoprene pads or

to the values of tables 4-12 through 4-15 if a

steel springs in series with two layers of ribbed or

well-designed and well-constructed floating floor

waffle-pattern neoprene pads. The density and

is used. Where careful designs have included

loading of the compressed glass fiber or neoprene

prevention of flanking paths of sound or vibra-

pads should follow the manufacturers' recommen-

dations. If steel springs are used, their static

tion, the table 4-16 values have been achieved

and even exceeded. However, if flanking paths

deflection should not be less than 1/4 inch. In some

systems the 2-inch space between the floating slab

are not prevented by intentional design consider-

ations, only one-half of these improvements may

and the structure slab is partially filled with a

be reached.

1-inch thickness of low-cost glass fiber or mineral

4-13

Previous Page

Previous Page