TM 5-805-4/AFJMAN 32-1090

where T is the turbocharger correction term (T = 0

where "rated MW" is the maximum continuous

dB for an engine without a turbocharger and T = 6

full-load rating of the engine in megawatts. If the

dB for an engine with a turbocharger) and L is the

manufacturer lists the rating in "effective shaft

length, in ft., of the exhaust pipe. A turbocharger

horsepower" (eshp), the MW rating may be approx-

takes energy out of the discharge gases and results

imated by

in an approximately 6-dB reduction in noise. The

MW = eshp/1400.

octave band PWLs of unmuffled exhaust noise are

O v e r a l l PWLs, obtained from equations C-9

obtained by subtracting the values of table C-19

through C-11, are tabulated in table C-20 for a

from the overall PWL derived from equation C-8. If

useful range of MW ratings.

the engine is equipped with an exhaust muffler, the

(1) Tonal components. For casing and inlet

final noise radiated from the end of the tailpipe is

noise, particularly strong high-frequency sounds

the PWL of the unmuffled exhaust minus the

may occur at several of the upper octave bands.

insertion loss, in octave bands, of the muffler.

However which bands contain the tones will de-

pend on the specific design of the turbine and, as

C-15. Gas Turbine Engines.

such, will differ detween models and manufactur-

a. PWL of three sources. As with reciprocating

ers. Therefore, the octave band adjustments of

engines, the three principal sound sources of turbine

table C-21 allow for these peaks in several differ-

engines are: the engine casing, the air inlet, and the

ent bands, even though they probably will not

exhaust. Most gas turbine manufactures will pro-

occur in all bands. Because of this randomness of

vide sound power estimates of these sources. How-

peak frequencies, the A-weighted levels may also

ever when these are unavailable the overall PWLs

vary from the values quoted.

of these three sources, with no noise reduction

(2) Engine covers. The engine manufacturer

treatments, are given in the following equations:

sometimes provides the engine casing with a pro-

for engine casing noise,

tective thermal wrapping or an enclosing cabinet,

Lw = 120 + 5 log (rated MW);

(eq C-9)

either of which can give some noise reduction.

for air inlet noise,

Table C-22 suggests the approximate noise reduc-

Lw = 127 + 15 log (rated MW);

(eq C-10)

tion for casing noise that can be assigned to

for exhaust noise

different types of engine enclosures. Refer to the

Lw = 133 + 10 log (rated MW);

(eq C-11)

notes of the table for a broad description of the

enclosures. The values of table C-22 may be

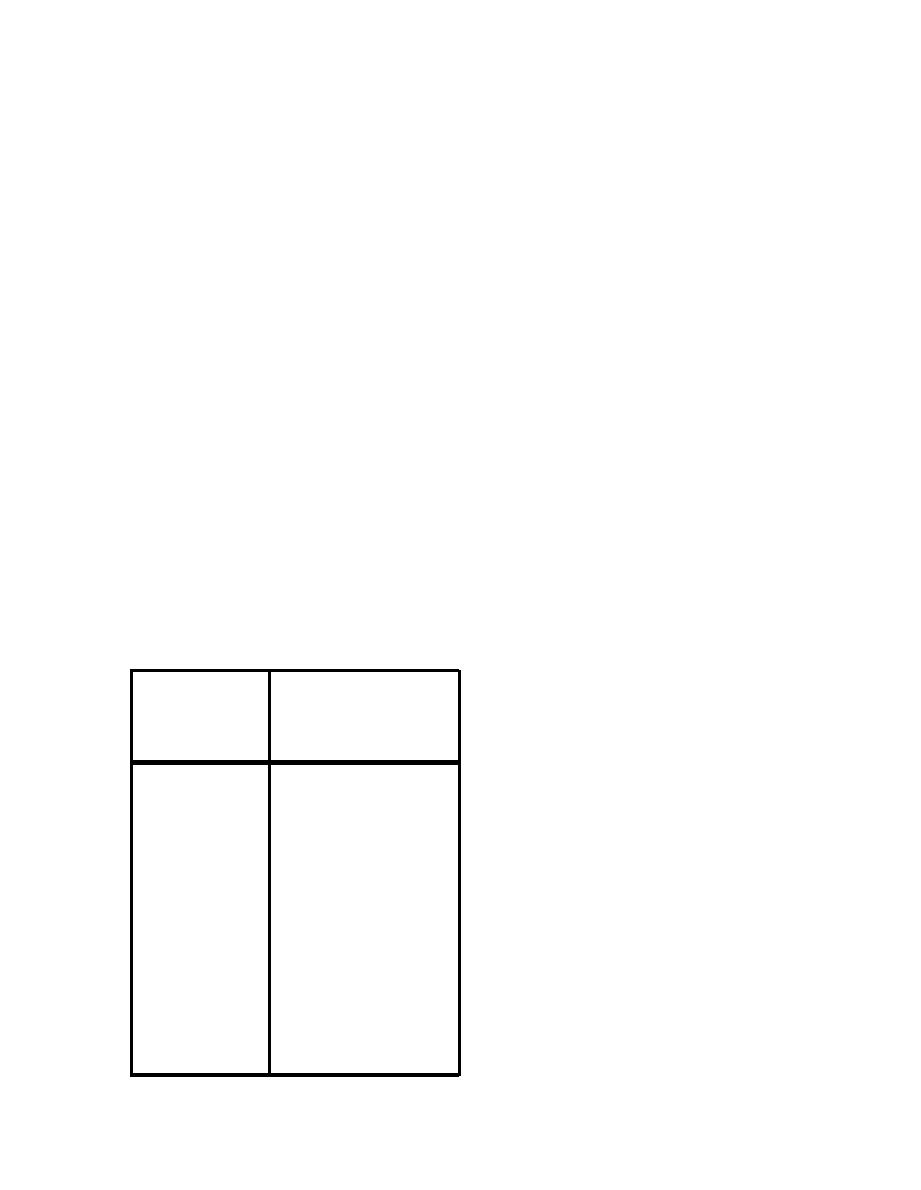

Table C-19. Frequency Adjustments (in dB) for Unmuffled

subtracted from the octave band PWLs of casing

Engine Exhaust Noise.

noise to obtain the adjusted PWLs of the covered

or enclosed casing. An enclosure specifically de-

Octave

Value to

signed to control casing noise can give larger noise

be Subtracted

Frequency

reduction values than those in the table. However

From Overall PWL

Band

it should be noted that the performance of enclo-

(Hz)

(dB)

sures that are supported on the same structure as

the gas turbine, will be limited by structure borne

31

5

sound. For this reason care should be used in

applying laboratory data of enclosure performance

63

9

to the estimation of sound reduction of gas turbine

enclosures.

3

125

b. Exhaust and intake stack directivity. Fre-

7

250

quently, the exhaust of a gas turbine engine is

directed upward. The directivity of the stack pro-

15

500

vides a degree of noise control in the horizontal

1000

19

direction. Or, in some installations, it may be

beneficial to point the intake or exhaust opening

2000

25

horizontally in a direction away from a sensitive

4000

35

receiver area. In either event, the directivity is a

factor in noise radiation. Table C-23 gives the

8000

43

approximate directivity effect of a large exhaust

opening. This can be used for either a horizontal

A-weighted,

12

or vertical stack exhausting hot gases. Table C-23

dB (A)

shows that from approximately 0 to 60 degrees

from the axis of the stack, the stack will yield

C-16

Previous Page

Previous Page