UFC 3-460-03

21 JANUARY 2003

4.4.7. Remote Controls (Electrical):

4.4.7.1. Fixed Control Stations. The original joy-cable fixed control stations on Type I hydrant

systems should have been converted to the magnetic control switches similar to the KISS switches

used in the Type II system.

4.4.7.2. Emergency Switches. Emergency switches are single-pole-type and connected in series

with the power supply line to the control equipment in the operating pumphouse. The switches are

provided so operating personnel at any pit can stop all fueling operations in case of fire or other

mishap. After activation of an emergency switch, the controls in the operating pumphouses must

be manually reset to resume fueling.

4.4.8. Defueling Tank. A deep-well turbine pump is installed on the defueling tank to transfer the

product to bulk storage or operating tanks. The defueling tank should be equipped with a high-level

alarm to warn personnel that the fuel level in the tank is approaching the predetermined fill level, and

a high-level control valve to shut off the flow of fuel into the tank.

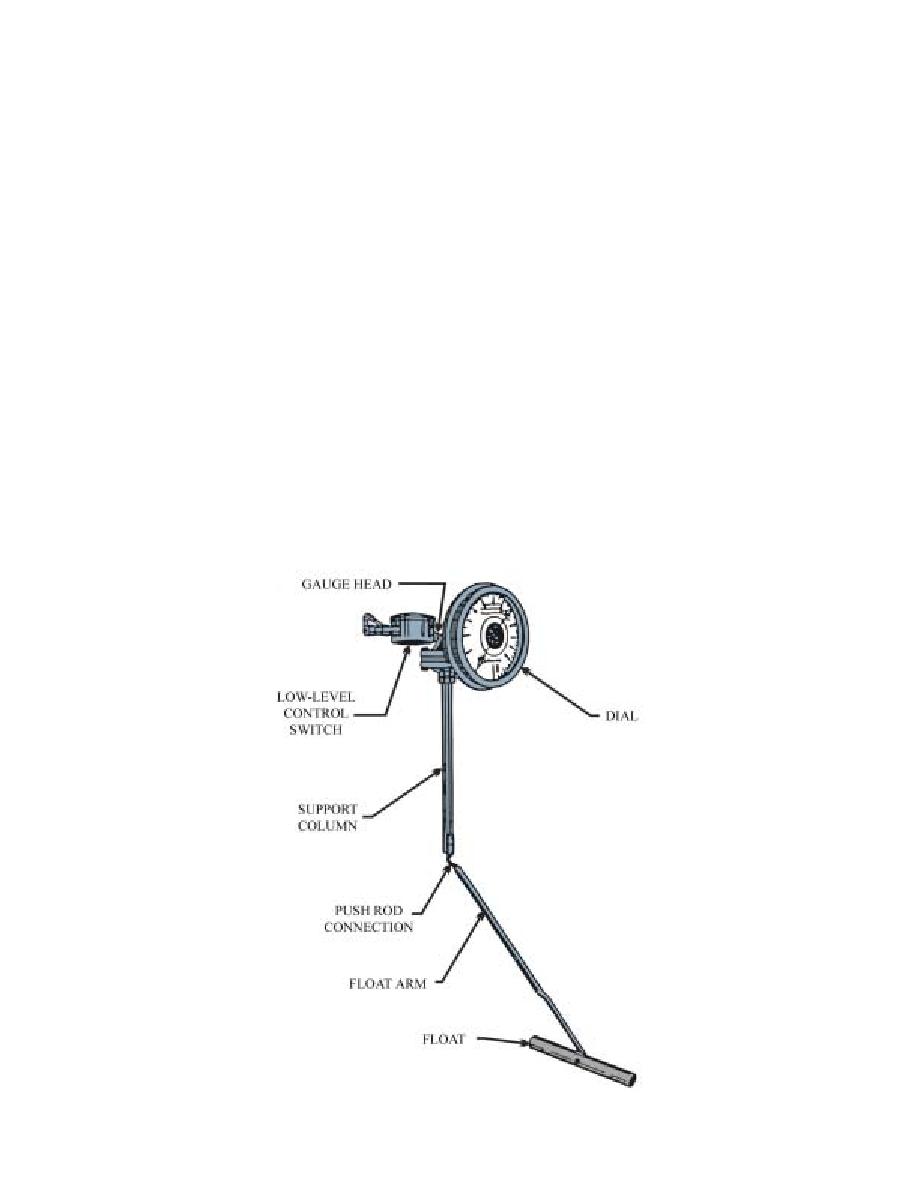

4.4.9. Liquid Level Gauge and Low-Level Control. A liquid level gauge and low-level control

(Figure 4.6) are installed to shut down the pump automatically. The liquid level gauge and the low-

level control prevents withdrawing fuel from the tank below a predetermined level (typically

330 millimeters [13 inches] on underground tanks), and prevents the pump from running dry.

Figure 4.6. Liquid Level Gauge (Liquidometer).

37

Previous Page

Previous Page