UFC 3 -520-01

June 10, 2002

6.0 kW

Corrected Battery Load (kW ) =

1.25 1.11 = 9.05 kW

0.92

Notice that the designer chose not to add design margin because the UPS is

already assumed to be fully loaded.

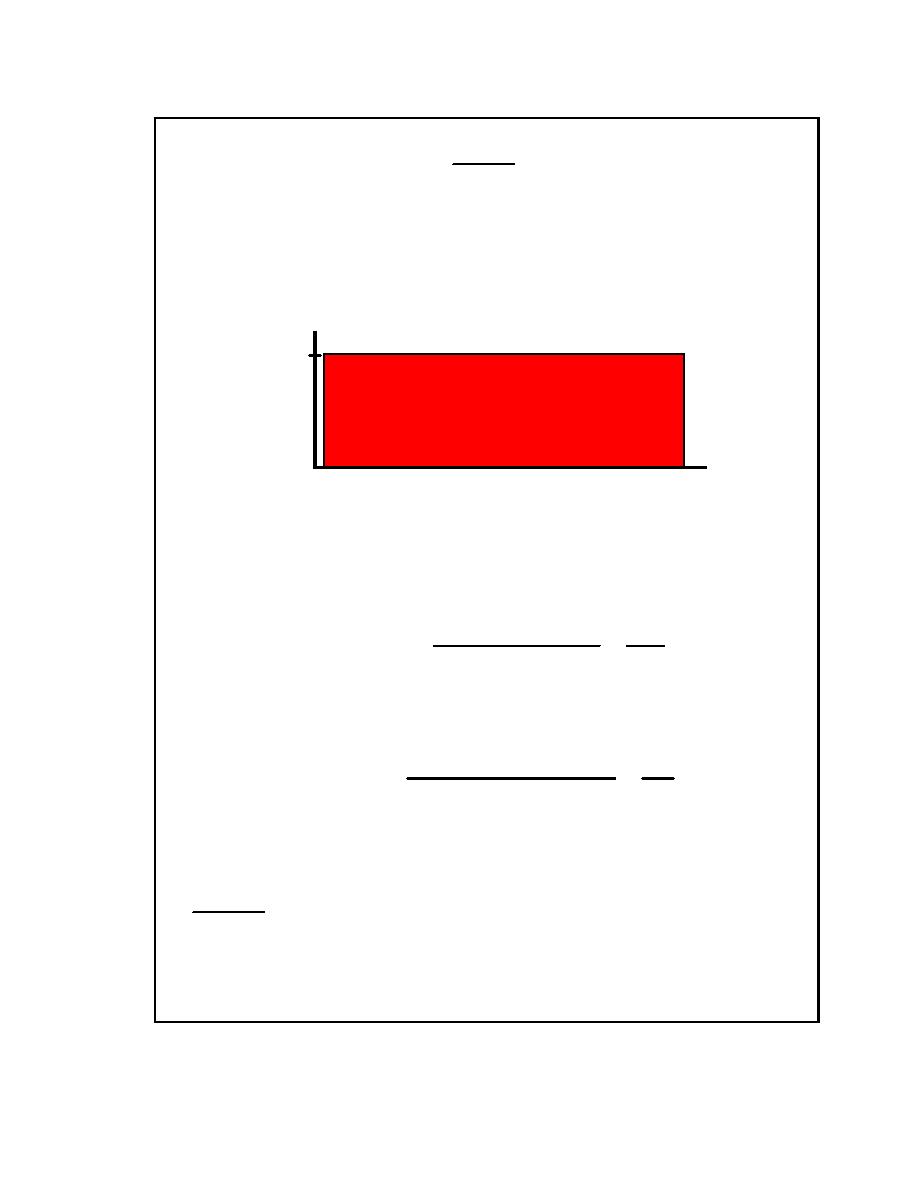

For this typical example, the duty cycle cons ists of the above constant load for 30

minutes.

9.05

Load

(kW)

0

30

Discharge Time (minutes)

The UPS maximum dc input voltage was specified as 140 volts. This voltage is

the maximum allowed voltage on the system. Also, assume that the

manufacturer recommends a maximum battery equalize voltage o f 2.33 volts per

cell. The maximum number of cells is given by:

Max System Voltage

140

Maximum Number of Cells =

=

= 60.09 cells

Equalize Voltage

2.33

In this case, choose 60 cells. Next, determine the minimum allowed voltage per

cell based on the system minimum voltage requirement of 105 volts:

Minimum System Voltage

105

Minimum Cell Voltage =

=

= 1.75 volts

Number of Cells

60

The designer needs 60 cells capable of providing 9.05 kW for 30 minutes without

allowing voltage to drop below 1.75 volts per cell. Each cell must deliver:

9.05 kW

= 0.151 kW per cell

60 cells

This is the information needed to select a cell from the manufacturer's d ata

sheets. Each cell must be capable of providing 0.151 kW for 30 minutes without

individual cell voltage falling below 1.75 volts.

E-2.3

Refer to IEEE 1184, IEEE Guide for the Selection and Sizing of Batteries for

Uninterruptible Power Supply Systems, for additional information regarding sizing of

UPS batteries.

E-6

Previous Page

Previous Page