UFC 3 -520-01

June 10, 2002

E-4.2

Size the charger to be large enough to supply the normal continuous loads

while also recharging the battery within a reasonable time period. The charger sizing

formula is as follows:

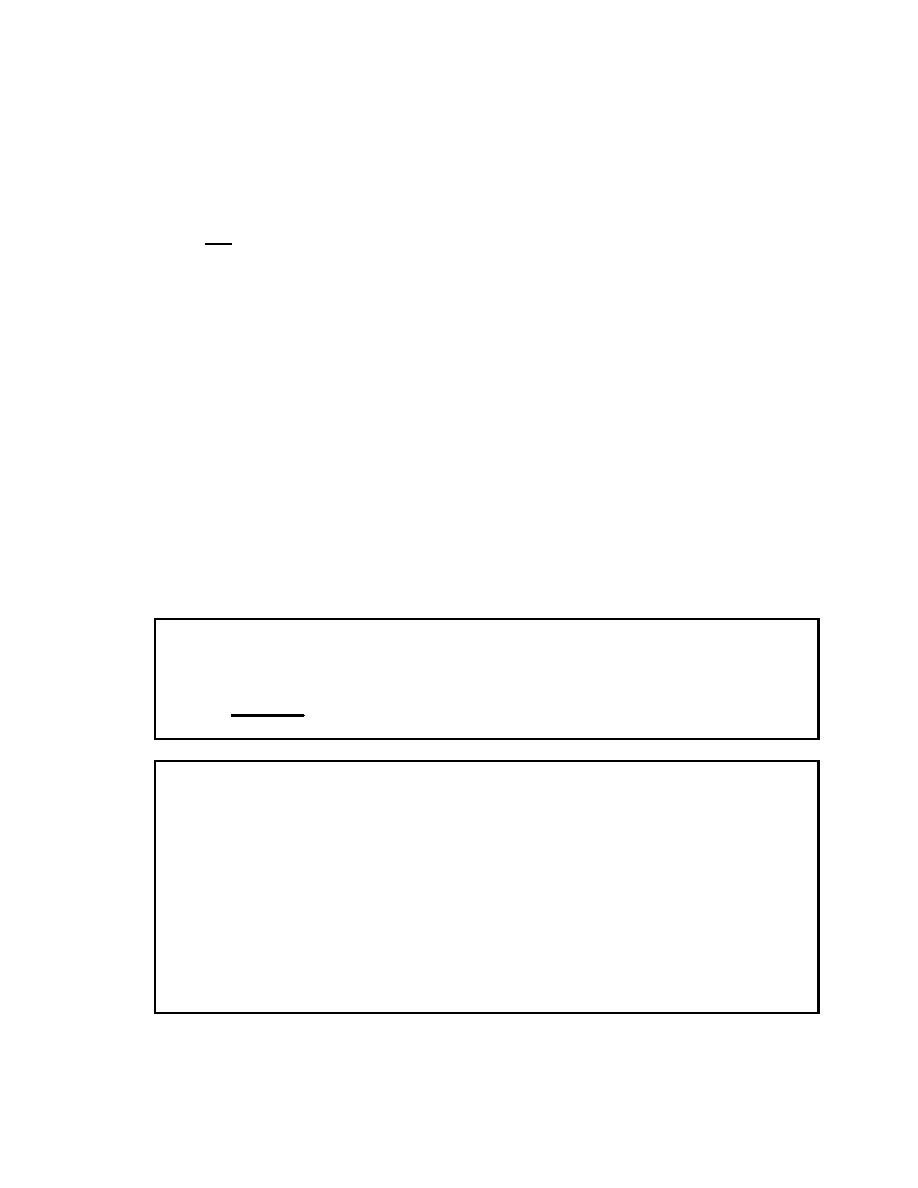

kC

A=

+ Lc

H

where

A

= Output rating of the charger in amperes.

k

= Efficiency factor to return 100 percent of ampere-hours removed.

Use 1.1 for lead-acid batteries and 1.4 for nickel-cadmium

batteries.

C

= Calculated number of ampere-hours discharged from the battery

(calculated based on duty cycle).

H

= Recharge time to approximately 95 percent of capacity in hours. A

recharge time of 8 to 12 hours is usually recommended.

Lc

= Continuous load (amperes).

E-4.3

The above sizing method is recommended, but tends to provide an optimistic

recharge time. The actual recharge time is usually lo nger than indicated above

because the charging current tends to decrease as the battery voltage increases during

recharge.

EXAMPLE: Determine the charger rating if a) the continuous load is 100

amperes, b) 300 ampere -hours are discharged from a lead-acid battery, and c)

the battery is to be recharged within 10 hours.

1.1 300

A =

+ 100 = 133 amperes

10

EXAMPLE: Suppose that the above system has 50 amperes of noncontinuous

loads that can be energized at any time. In this case, the total charger load is the

sum of the continuous and noncontinuous load before consideration of battery

recharge requirements. At any time, the charger load can be as high as:

A = Lc + Ln = 100 + 50 = 150 amperes

If the charger in the previous example was selected to have a capacity of 133

amperes, the battery would have to supply the additional load whenever the

noncontinuous load is energized. So, the charger should instead be sized to

provide the expected system loads, or 150 amperes in this example. Note that

this assumes the noncontinuous loads will not be energized for long periods

when the battery is being recharged.

E-9

Previous Page

Previous Page