MIL-HDBK-1025/10

Table 18 (Continued)

Sequence of Lockout/Tagout/Tryout Steps

II. Re-energizing steps

A. Inspect the work area for an operationally intact system and remove nonessential items.

B. Notify all affected workers of system re-energizing. Warn them to stand clear.

C. Remove temporary grounding.

D. Remove the lockout/tagout/tryout devices.

E. Visually determine that all affected workers are clear of the circuit.

F. Proceed with restoring service.

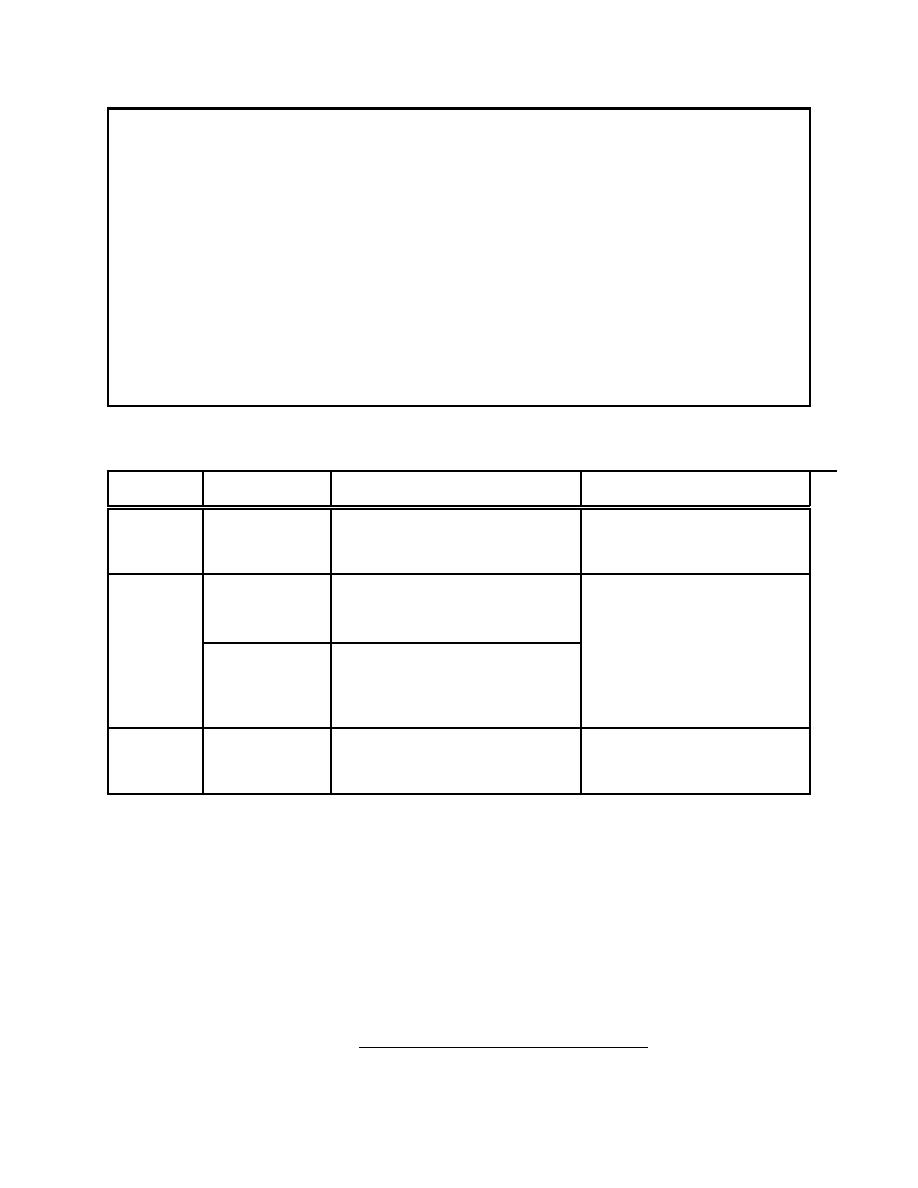

Table 19

Tag Requirements

Color

Warning

Use for

Do not use for

DANGER

Tagout for de-energizing a

Notes, cautions, warnings, or

RED

HOLD

circuit or equipment

tagging grounds

Informs personnel about an

CAUTION

unusual condition. Use for

notes, warnings, or cautions.

Tagging out an energy

YELLOW

isolating device.

Identifies equipment, which is

REPAIR

defective and needs repair. Use

for notes, warnings, or cautions.

GROUND

Indicates placement of a ground

For red or yellow tagging out

GREEN

PLACEMENT

on a circuit or equipment

requirements

5.2.2.3 Lock and Tag Color Coding. In the process of lockout/tagout/tryout,

the color coding RED for danger, YELLOW for caution, and GREEN for ground

placement will always be used as covered in Table 19. RED locks are used to prevent the

operation of a hazardous energy control device, generally a switching device. All RED

locks are keyed individually; that is they have no master key. Spaces on the tags are

provided for defining the hazard, the caution, and the ground placement. These spaces

should be filled in. The reverse side may contain additional data, including the name of the

individual responsible for the tag.

Grounding Provisions. Comply with the requirements of OSHA

5.3

standard 29 CFR 1926.269(n), Grounding and Protection of Employees. Grounding is

used to limit dangerous potentials. Permanent grounding is provided as a part of any

31

Previous Page

Previous Page