MIL-HDBK-1025/10

Table 22

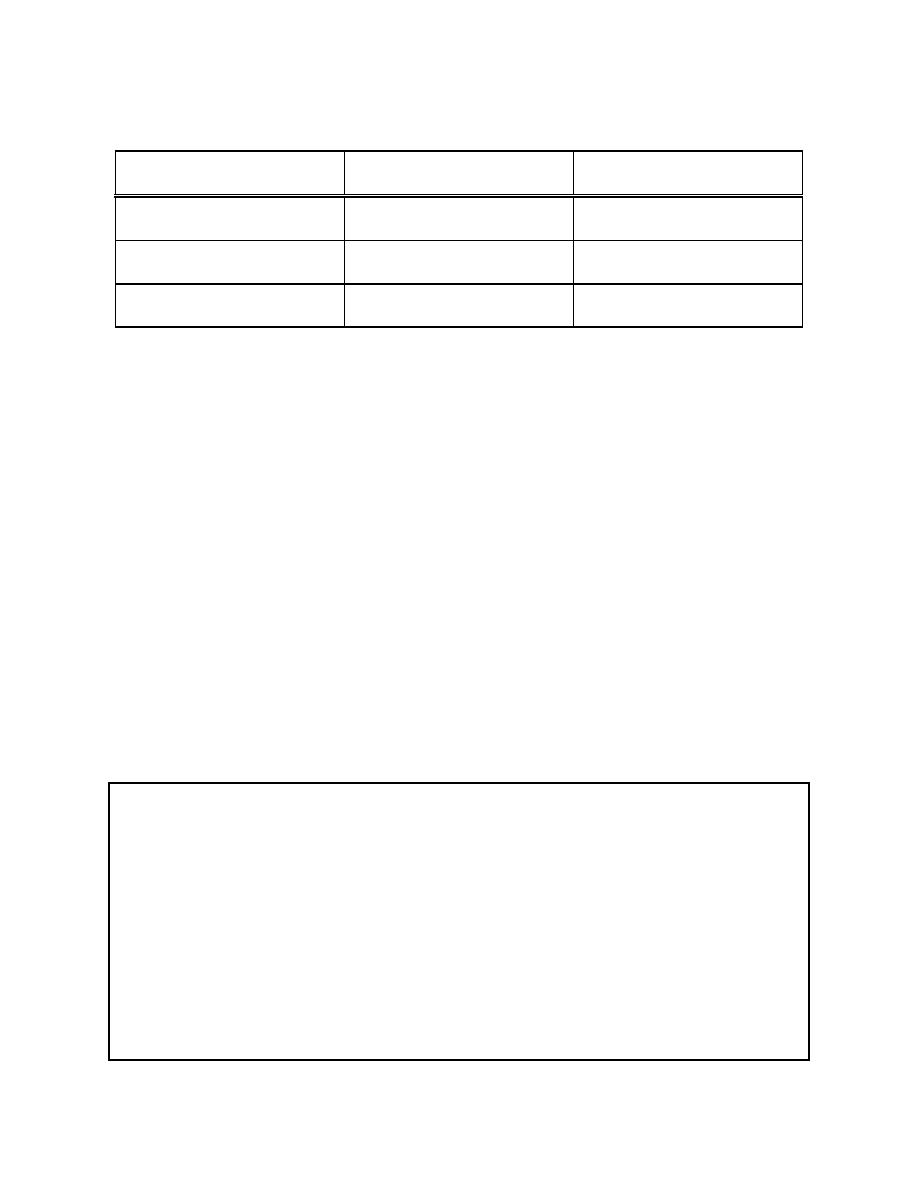

Maximum Fault Current Capability for Grounding Cables1

Cable size

Fault time

Root-mean-square amperes

(AWG)

(cycles)

(copper)

15

27,000

2/0

30

20,000

15

36,000

3/0

30

25,000

15

43,000

4/0

30

30,000

1

These current values are the "withstand rating" currents for grounding cables and cables as

per ASTM F 855. These values are about 70 percent of the fusing (melting) currents for

new copper conductors. They represent a current that a cable should be capable of

conducting without being damaged sufficiently to prevent reuse.

5.3.4.3 Grounding Ferrules. Use ASTM F 855, Type IV (threaded stud copper

base compression type) when installed on grounding cables by facility personnel. Ferrules

should have the filler compound vent hole at the bottom of the cable so that workers can

visually check that the cable is fully inserted into the ferrule. Heat shrink or springs should

be installed over a portion of the ferrule to minimize strand breakage caused by bending.

In all cases, the manufacturer's recommendations should be followed. Do not use

aluminum alloy ferrules as they will not provide a lasting snug fit. Check for tightness

periodically.

5.3.4.4 Grounding Cluster Bars. Use to connect phase and neutral conductor

jumper cables to the selected method of providing a ground electrode (pole ground wire,

temporary ground rods, substation ground grid). Cluster bars should have an attached

bonding lead. Provide temporary ground rods as given in Table 23.

Table 23

Temporary Ground Rod Minimum Requirements

I.

Single rod installed to a depth of 1.5 meters (5 feet) below grade.

A. A minimum 16-millimeter (5/8-inch) diameter bronze, copper, or copper-weld rod at

least 1.8 meters (6 feet) long.

B. A 1.8-meter (6-foot) long, screw-type ground rod, consisting of a minimum 16-

millimeter (5/8-inch) diameter copper-weld shaft with a bronze auger bit and bronze

T-handle, tightly connected to the rod.

II. Additional rods to provide additional 1.5 meters (5 feet) lengths below grade where

required.

A. Install 1.8 to 2.4 meters (6 to 8 feet) apart while maintaining the 3-meter (10-foot) step

and touch potential clearance.

B. Bond all rods together prior to installing other electrode connections.

35

Previous Page

Previous Page