MIL-HDBK-1025/10

Table 32

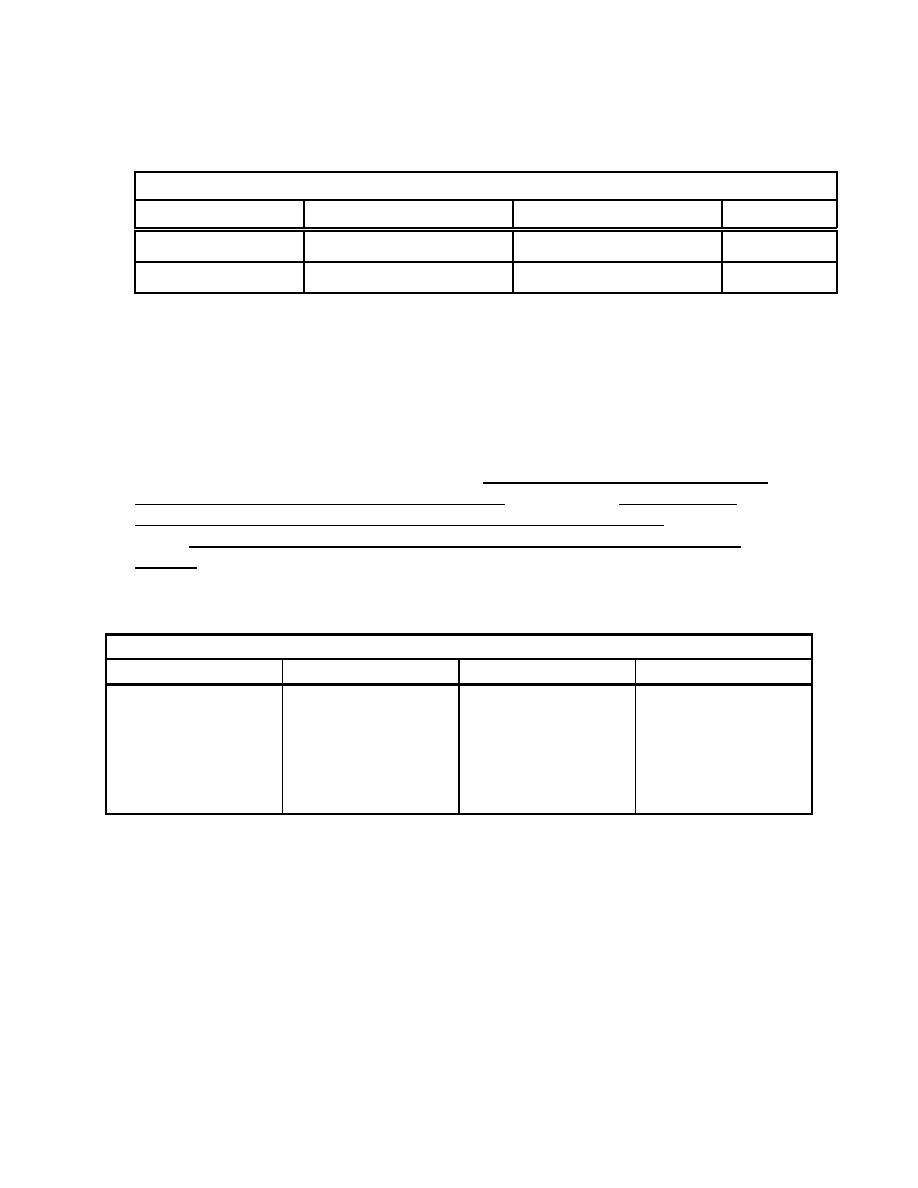

Insulating Tools for Electrical Workers

Minimum test values

OSHA acceptance1

IEEE in-service2

Tool material

Use

Preferred3

FRP

0.3 meters (100 kV/foot)

0.3 meters (75 kV/foot)

Phase-out4

Wood

0.3 meters (75 kV/foot)

0.3 meters (50 kV/foot)

1

Test values manufacturers should certify for acceptance by buyer.

2

Test values required after acceptance and tested after use in the field. Electrically test at

intervals of not more than 6 months for tools in frequent use. Electrically test at intervals of

not more than one year for tools stored for long periods of time.

3

All new tools will be FRP.

4

Replace wood hot line tools with FRP tools.

5.4.2.3 Insulating Guards. Use insulating plastic guard equipment meeting the

requirements of Tables 33 and 34; ASTM F712, Test Methods for Electrically Insulating

Plastic Guard Equipment for Protection of Workers; ASTM F 968, Specification for

Electrically Insulating Plastic Guard Equipment for Protection of Workers; and ASTM F

15684, Specification for Structure Mounted Insulating Work Platforms for Electrical

Workers.

Table 33

Common Classification for Plastic Guards

Common classifications for plastic guards

Installation

Conductors

Structure/apparatus

Special

Attached hot stick

Line guards

Pole guards

Shape

Eye for removable hot Line guard connectors Ridge pin covers

Size

stick

Insulator covers

Switchblade covers

Attachment

Rope loop or

Deadend covers

Arm guards

More stringent

equivalent for gloving Bus guards

Cutout covers

electrical requirements

or hot stick

Bus "T" guards

Crossarm guards

45

Previous Page

Previous Page