UFC 4-152-01

28 July 2005

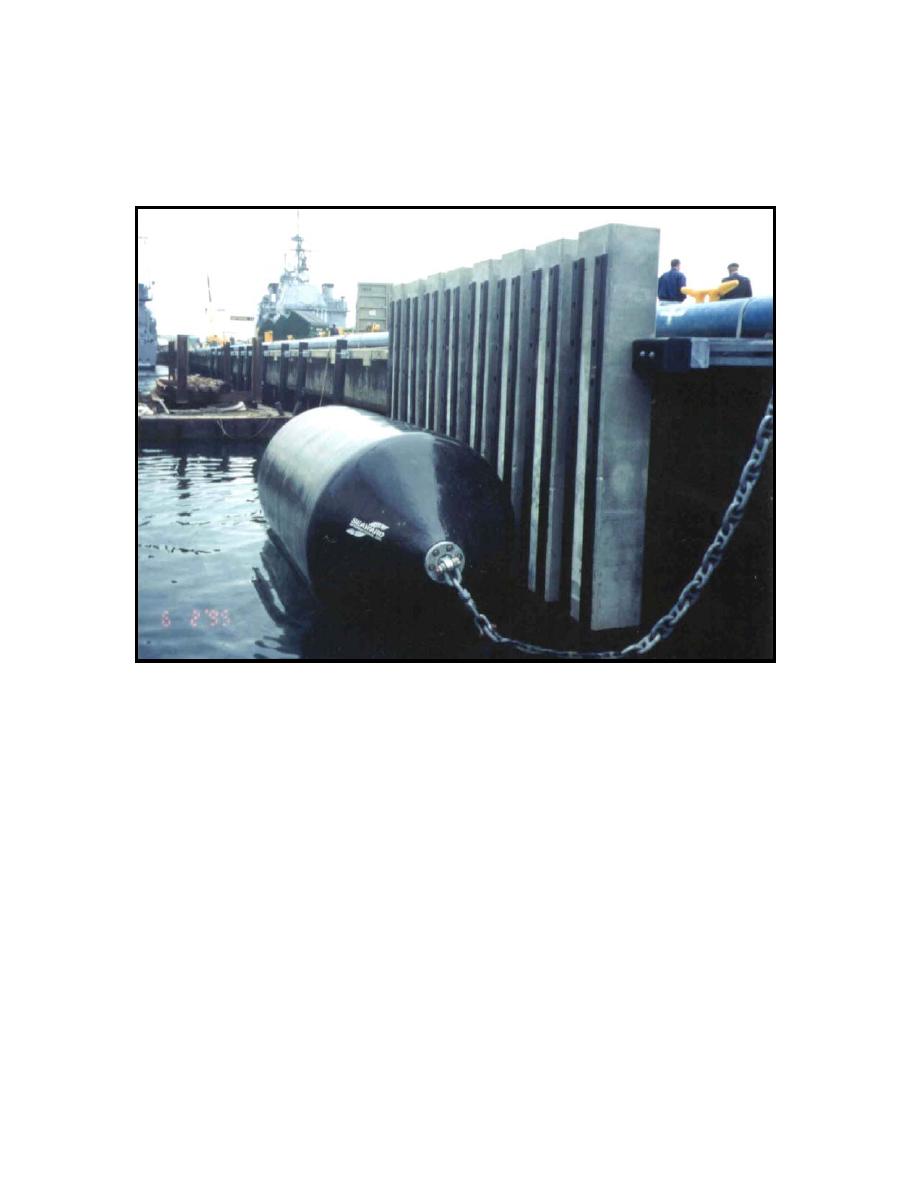

Figure 5-5 Foam-filled Fender System.

Foam-filled fender, concrete fender piles, steel frame and polyethylene rub strips.

(Marine Fender Systems, by T.E. Spencer, ASCE PORTS 2004).

5-3.2.4

Composite Fender Piles.

There are two primary types of composite fender piles. One type of composite

pile is made of fiber reinforced plastic (FRP) in the form of a tube that can be

filled with concrete for greater strength and stiffness. Figure 5-6 shows an FRP

fender pile system. Because of a higher susceptibility to abrasion and impact

damage, the thermoset FRP tube type pile should have rubberized abrasion

strips installed at potential contact points with berthed vessels.

The second type of composite pile is made of thermoplastics (such as high-

density polyethylene, HDPE) and reinforced with either steel or FRP strands.

Figure 5-7 shows a plastic fender pile system. The reinforced thermoplastic type

pile generally exhibit larger load-deflection properties compared to conventional

wood, steel or concrete piles. To ensure uniform loading and avoid premature

failure of fender system components, these type piles should not be used in

parallel or mixed with conventional type piles in the same system. Relevant work

to date on composite fender piles includes TM-2158-SHR. Follow on work to this

is contained in SP-2005-SHR, which includes flexural load tests to failure and

cyclic tests to determine the stiffness (EI), load/deflection, linerarity, hysteresis,

111

Previous Page

Previous Page