TM 5-850-1

CHAPTER 10

MOORING DEVICES

10-1. Typos.

type of device and its anchorage. These devices and

The types of mooring devices most commonly used in

their anchorages should be designed to withstand a

the berthing of both deep and shallow-draft vessels are

force 50 percent greater than the breaking strength of an

as follows:

attached hawser. The mooring force may be assumed

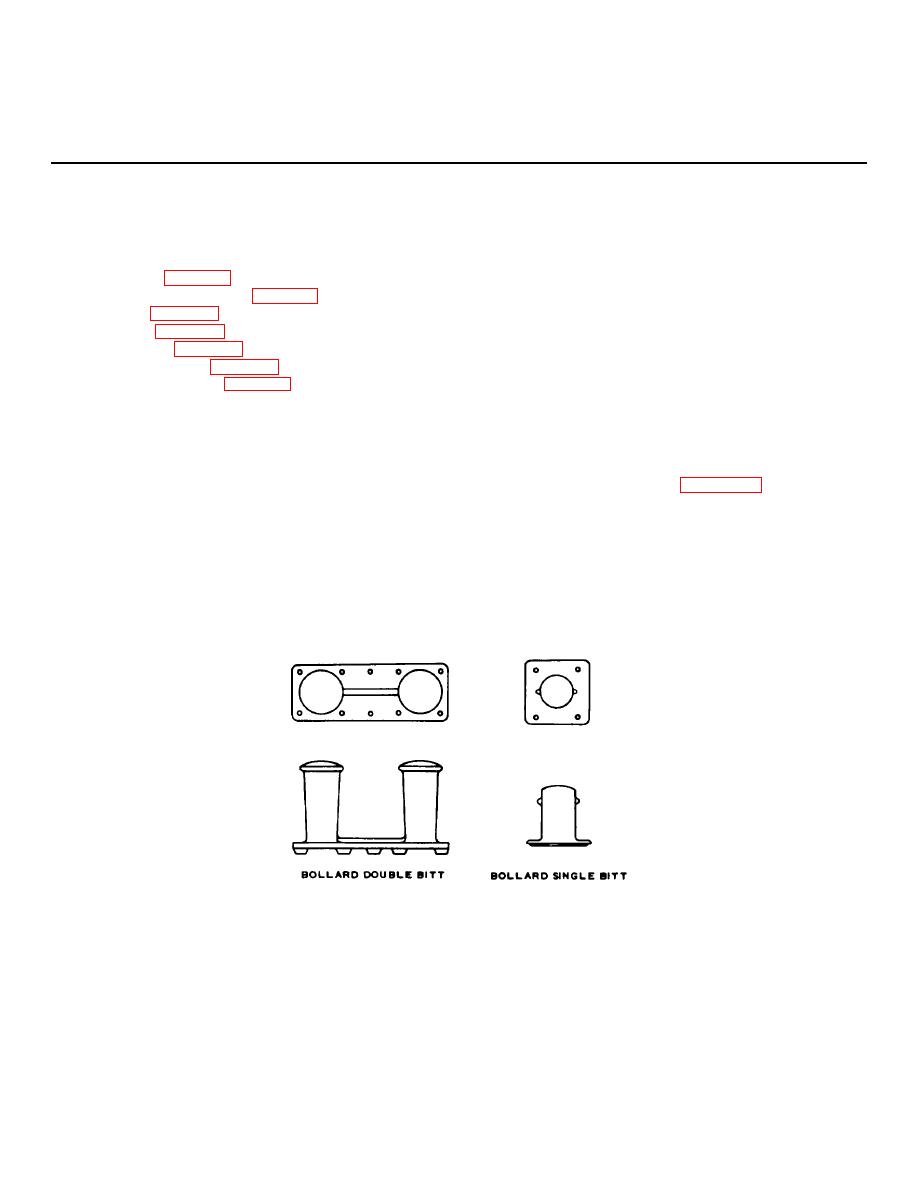

a.

in its most unfavorable design position, which is

Bollards(fig. 10-1)

b.

ordinarily horizontal and perpendicular to the long axis

Corner mooring post (fig. 10-2)

c.

of the device when under stress. Furthermore, the

Cleats(fig. 10-3)

d.

capacity of a device of given size and shape will be

Chocks(fig. 10-4)

e.

affected by the type of metal used in its manufacture.

Pad eyes (fig. 10-5)

f.

Devices are normally available in cast iron, ductile iron,

Power capstan (fig. 10-6)

or cast steel in various stress-grades of each metal.

g.

Releasing hooks (fig. 10-7)

b. Spacing. The types and spacing chosen for a

10-2. Capacity and spacing.

specific berth should be based upon the characteristics

and convenience of the using vessel.

A typical

Mooring devices should be adequate in size, number,

arrangement of mooring devices to service both small

and spacing to resist the forces of wind, current, waves,

and large vessels is shown in figure 10-8.

ice, and other related natural elements.

10-3.

Anchorage.

a. Capacity.

Mooring devices are sometimes

assigned design capacities by the manufacturers.

Mooring devices should be anchored firmly to their

However, the specific operating conditions at a given

supporting structure. The uplift, horizontal forces, and

berth should be considered in assessing the capacity of

overturning moments may be considered in selecting

any

types of anchorage.

Department of the Army

Figure 10-1. Single and double bitt bollards

10-1

Previous Page

Previous Page