TM 5-628/AFR 91-44

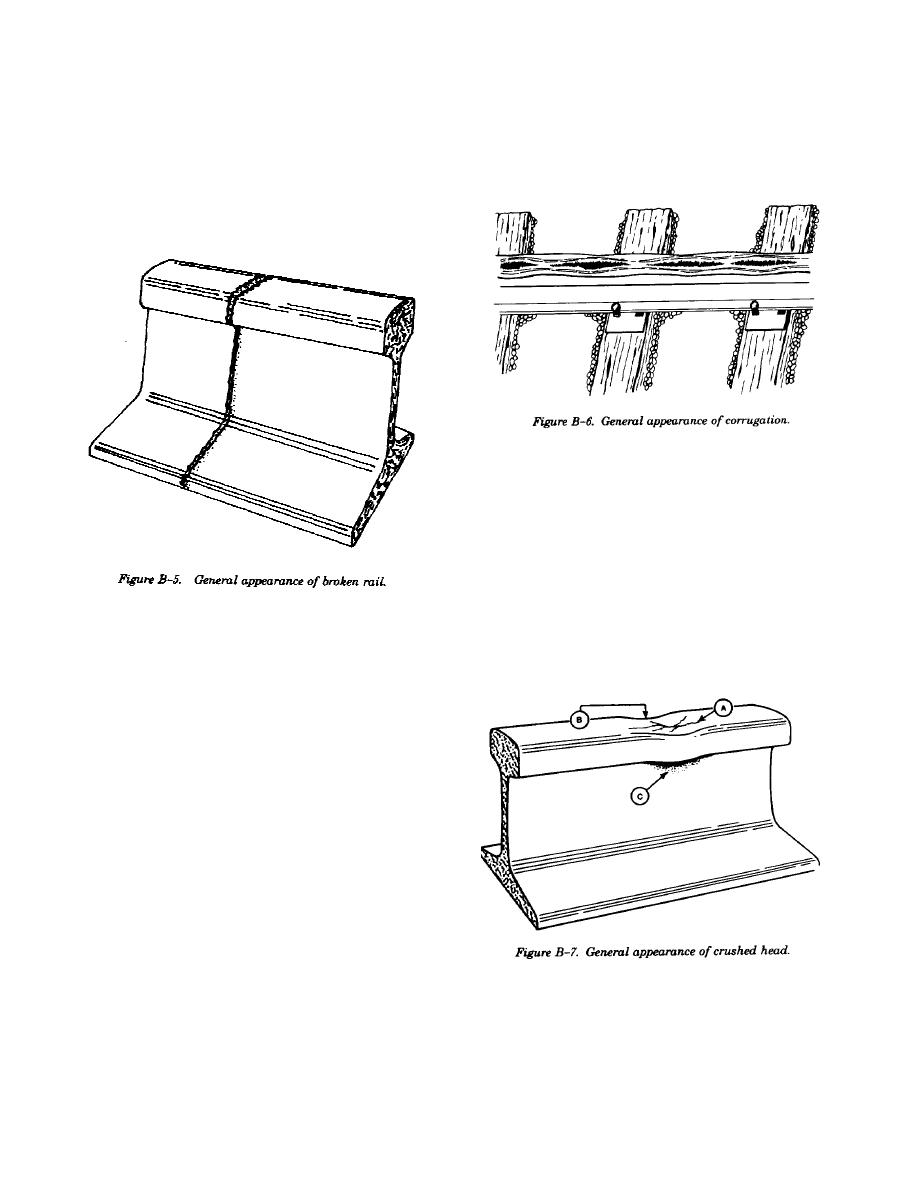

c. Complete break (broken rail).

of the rail varying anywhere from 2 to 18 inches

apart and usually less than 1/16 (0.0625) inch deep.

(1) Description. A complete transverse

separation of the head, web, and base of the rail.

Although the individual waves (ridges) are usually

(2) Appearance in track. May appear as a

only a short distance apart, the corrugations may

hairline crack running completely around the rail,

extend over a considerable distance (see fig B-6).

usually accompanied by bleeding or a separation of

the rail at the break with one or both of the broken

ends battered down (see fig B-5).

g. Crushed head.

(1) Description. The flattening of several

inches of the rail head, usually accompanied by a

crushing down of the metal but with no signs of

cracking in the fillet under the head.

(2) Appearance in track. Generally appears

as:

(a) Flattening and widening of the head

for several inches with the entire head sagging.

d. Compound fissure. See "transverse defects."

(b) Small cracks in a depression on the

e. Corrosion.

running surface.

(1) Description. The decaying or corroding

of the metal in the web or base of the rail.

may be present at the fillet under the head (fig B-

(2) Appearance in track. Pits or cavities in

7).

the upper base or the web of the rail. In advanced

stages, a significant loss of material is evident.

f. Corrugation.

(1) Description. A repeated wavelike

pattern on the running surface of the rail.

Corrugations develop over a long period of time. A

number of factors contribute to the development of

corrugations with the actual cause dependent on

the track and operating conditions. Corrugations

are not a critical defect.

(2) Appearance in track. Small, hard,

bright, short-pitch ridges along the running surface

B-3

Previous Page

Previous Page