TM 5-628/AFR 91-44

h. Defective weld.

(1) Description. A progressive transverse

separation within an area where two rails have been

joined by welding or a rupture at a weld where im-

proper fusion has occurred.

(2) Appearance in track. No outward sign

is visible until the separation reaches the rail sur-

face. A defective weld may then be recognized by

a vertical bleeding crack at the welded portion of

the rail joint where the separation has reached the

surface.

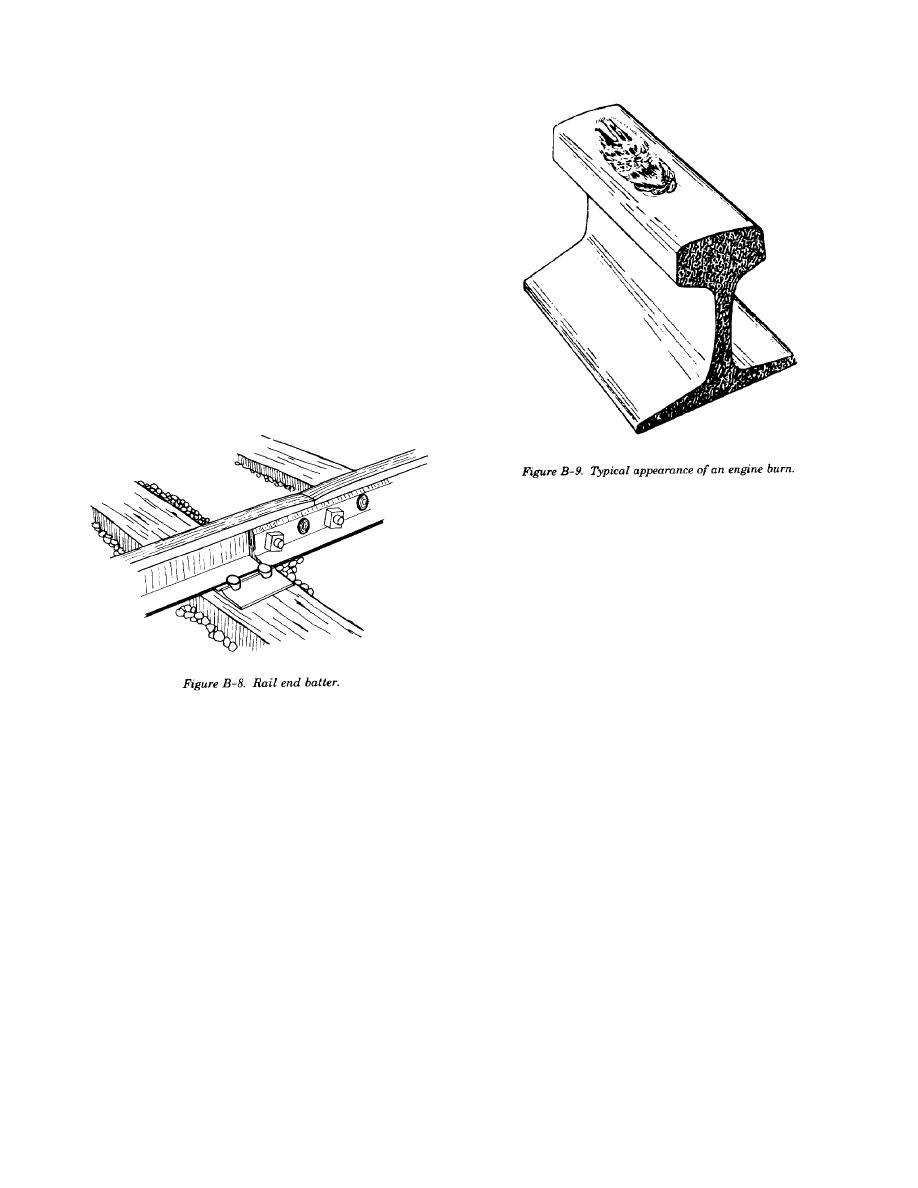

j. End batter.

(1) Description. Damage caused by wheels

striking the rail ends.

(2) Appearance in track. Appears as

damage to or a depression in the top surface of the

rail head at the ends of the rail (fig B-8).

l. Engine burn fracture.

(1) Description. A progressive fracture in

the rail head starting from a point where engine

wheels have slipped and burned the rail.

(2) Appearance in track. No sign of

transverse separation is visible until the defect

reaches the rail surface (cracks out). An engine

burn fracture may then be recognized by one or

more of the following characteristics.

(a) A hairline crack on the side of the

head in the immediate vicinity of an engine burn

and at right angles to the running surface. The

k. Engine burns (burned rail).

crack may be visible on either the field or gage side

(1) Description. Rail that has been scarred

of the head.

(b) Transverse thermal cracks extending

on the running surface by the friction of slipping

locomotive wheels. An engine burn is not a critical

from the burn to the gage corner and down the side

of the head for at least c (0.125) inch.

defect; however, an engine burn may lead to an

(c) A cracked out horizontal separation on

engine burn fracture.

(2) Appearance in track. Round or oval

the field side of the rail head under the burned area

rough spots or holes on the tread of the running

often accompanied by one or more thermal cracks

surface. Often the source of engine burn fractures.

extending transversely to the gage corner (fig B-10).

Engine burns may be deep (fig B-9).

B-4

Previous Page

Previous Page