TM 5-815-1/AFR 19-6

13-4.

Fluidized bed performance

predicted nitrogen oxide emissions.

e. Several fluidized bed boiler manufacturers are

a. With the exception of a baghouse or precipitator,

now offering performance guarantees based upon

which is required for particulate removal, additional

experience in the bubbling, circulating, and dual bed

gas cleaning devices are not required for environmental

designs.

control with fluidized bed systems.

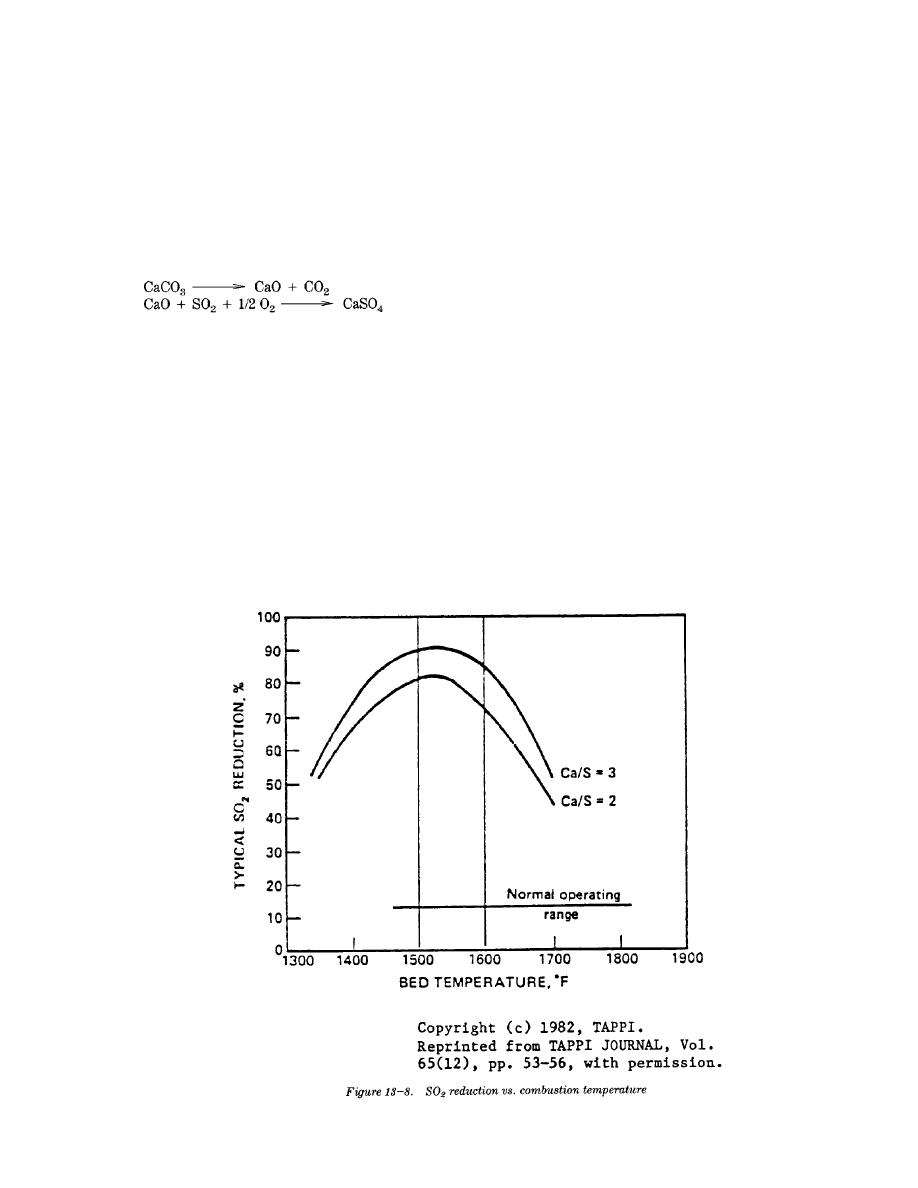

b. Fluidized bed boilers are able to remove sulfur

13-5.

Materials and construction

dioxide directly in the combustor. This is accomplished

by using limestone in the fluid bed. The limestone

The materials used for construction of fluidized bed

calcines to form calcium oxide (CaO) and then reacts

units are similar to those used in conventional boilers

with SO2 to form calcium sulfate as follows:

depending on the design pressure and temperature of

the system.

in-bed tubes have experienced high erosion rates in

some cases. Vertically oriented tubes are less prone to

The ideal temperature range for desulfurization in a

erosion than the horizontal ones. Where in-bed tubes

fluidized bed is about 1600 degrees Fahrenheit.

are used, consideration should be given to use of

c. A bubbling fluidized bed boiler will require a

thicker walls on the tubes and their metallurgy. Wear

higher calcium to sulfur ratio for control of SO2, while

fins can be installed to reduce erosion. Also, some

the circulating fluidized bed boiler can achieve similar

corrosion may be experienced due to the reducing

SO2 removal with the Ca/S ratio of 1.5 to 2. See figure

atmosphere in the lower regions.

b. Fluidized bed. The fluidized bed or bottom of the

13-8.

d. Nitrogen oxide is controlled by distribution of

combustor section varies considerably with each type

primary air under the bed and secondary air part way

of design. The method used for air distribution is

up the combustor. The staging of combustion limits the

important in maintaining uniform fluidization across

nitrogen oxide to that which is formed only by fuel-

the bed. Some units have had problems with plugging

bound nitrogen. Thermally formed nitrogen oxide is

of the air openings. The bottom is castable refractory-

negligible in the fluidized bed. See figure 13-9 for

lined on some units. Others have heat transfer tubes

13-8

Previous Page

Previous Page