TM 5-815-1/AFR 19-6

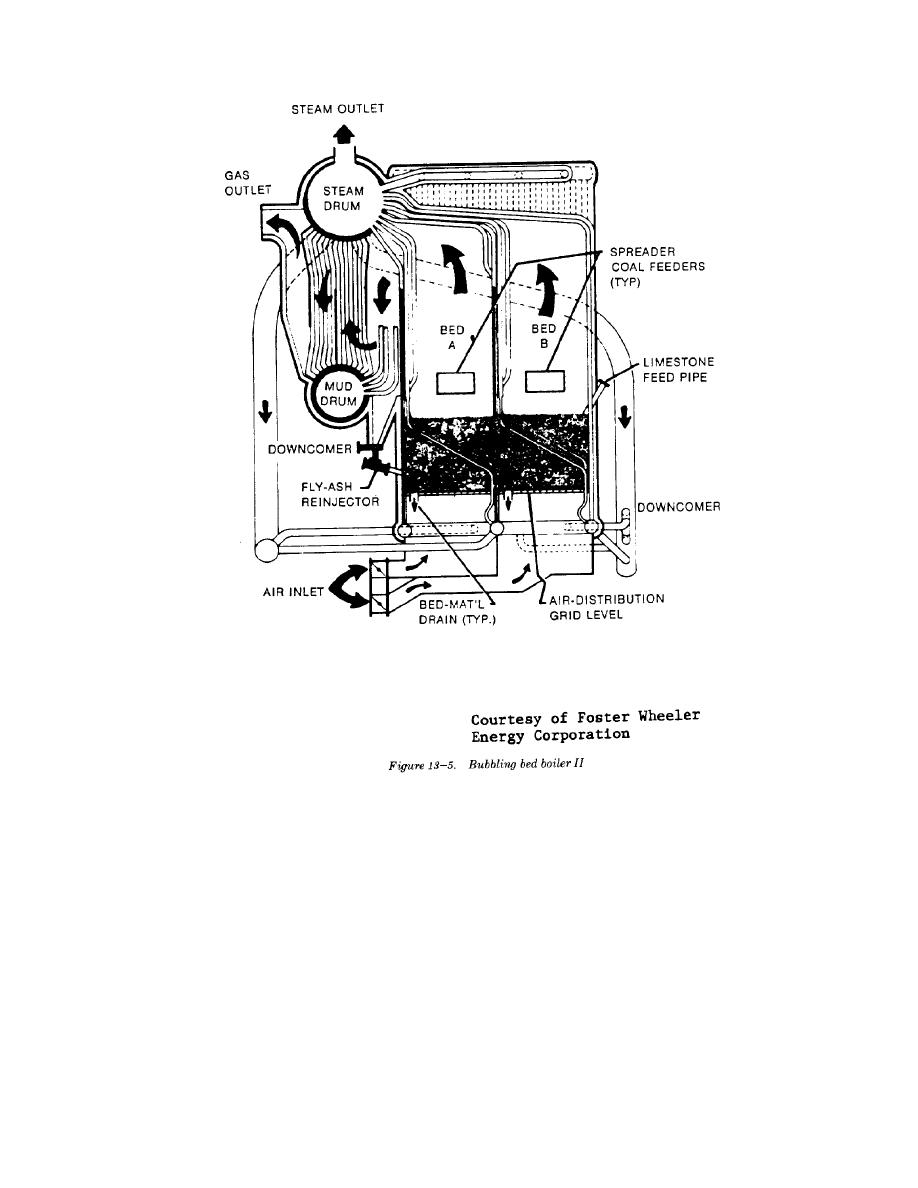

(g) Erosion of the heat transfer surface in the

desulfurization takes place. The dual bed

combustion chamber is reduced, since the

design allows coals to be burned at about

surface is parallel to the flow. In a

1750

degrees

Fahrenheit

while

bubbling bed system, the surface

desulfurization takes place at about 1550

generally is perpendicular to the flow.

degrees Fahrenheit. The upper bed also

serves to catch unburned coal particles that

and desulfurization take place in two separate beds,

may have escaped to complete combustion of

allowing each different reaction to occur under optimal

any unburned carbon.

conditions.

(3) A dual bed can be utilized on capacities up to

(1) The lower bed burns coal in a bed of sand,

200,000 pounds per hour of steam. The

fluidized from below by the combustion air

major advantages are: shop fabrication; can

and gases, and maintained at a steady

be retrofitted to some existing oil and gas

equilibrium temperature by the extraction of

fired boilers; enhanced combustion efficiency

energy through in-bed steam generator tubes.

by allowing the lower bed to operate at 1750

The bed depth is more shallow than the con-

degrees Fahrenheit; lower free-board heights

ventional bubbling bed design.

required; and better load following. A typical

(2) The flue gas then travels through an upper

dual bed fluidized combustor is shown in

bed of finely ground limestone where

figure 13-7.

13-5

Previous Page

Previous Page