TM 5-815-1/AFR 19-6

particles leave the combustion chamber with the flue

Desulfurization efficiency of a shallow bed is poor,

gases so that solids recirculation is necessary to main-

with only about 60 to 80 percent removal, because SO2

does not have adequate time to react with the limestone

tain the bed solids. This type of fluidization is called

circulating fluidized bed.

before moving out of the shallow bed. The shallow bed

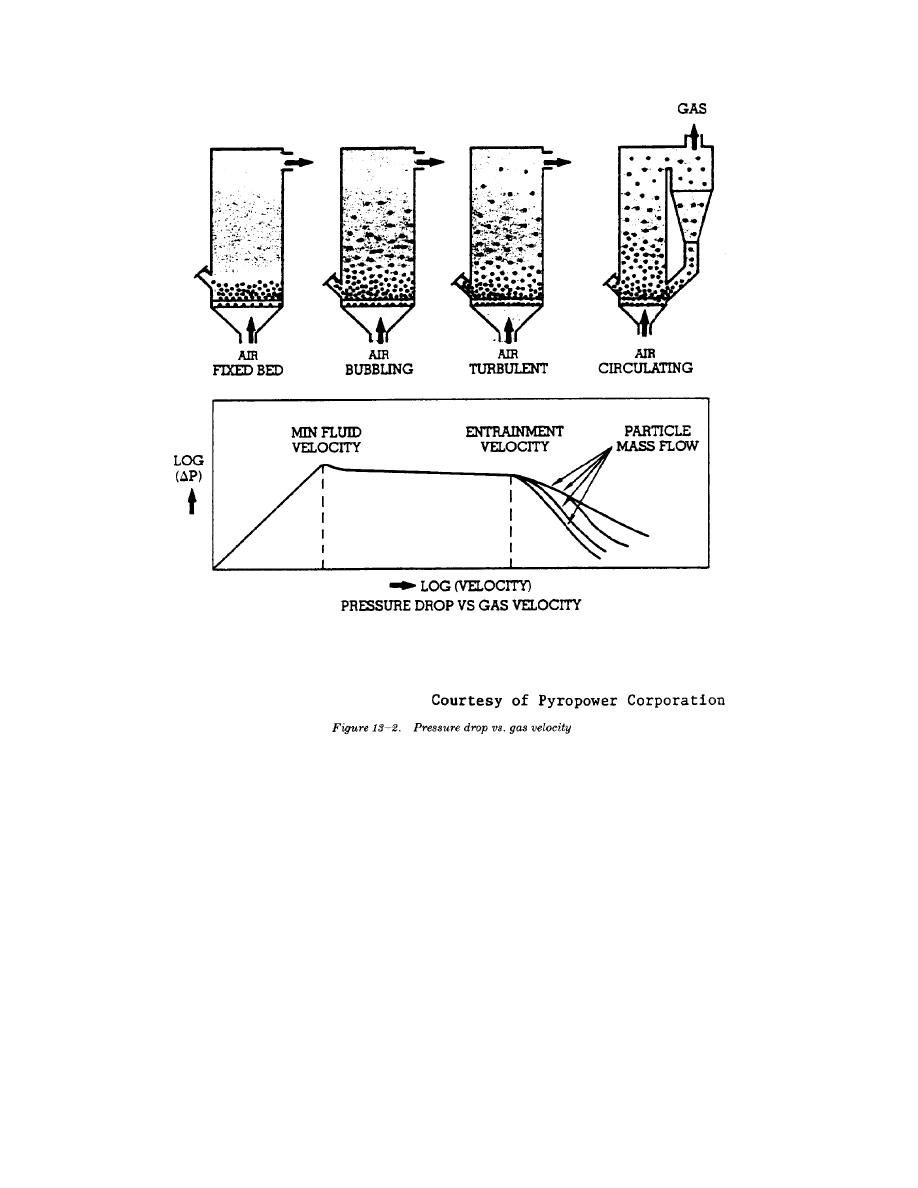

e. The mean solids velocity increases at a slower rate

fluidized boiler is of the bubbling bed design. The shal-

than does the gas velocity, as illustrated in figure 13-3.

low bed will be of very limited use because of its poor

Therefore, a maximum slip velocity between the solids

sulfur dioxide removal.

g. A deep fluidized bed boiler is a bubbling bed

and the gas can be achieved resulting in good heat

transfer and contact time with the limestone, for sulfur

design.

dioxide removal. When gas velocity is further

(1) The bed depth is usually 3 feet to 5 feet deep

increased, the mean slip velocity decreases again.

and the pressure drop averages about one

These are the operating conditions for transport reactor

inch of water per inch of bed depth. The bulk

or pulverized coal boiler. The design of the fluidized

of the bed consists of limestone, sand, ash, or

bed falls between the stoker fired boiler and the pul-

other material and a small amount of fuel.

verized coal boiler using the bed expansion.

The rate at which air is blown through the bed

f. The shallow fluidized bed boiler operates with a

determines the amount of fuel that can be

single bed at a low gas velocity. A shallow bed mini-

reacted. There are limits to the amount of air

mizes fan horsepower and limits the free-board space.

that can be blown through before the bed

The bed depth is usually about 6 inches to 9 inches and

material and fuel are entrained and blown out

the free-board heights are only four to five feet.

13-2

Previous Page

Previous Page