TM 5-815-1/AFR 19-6

CHAPTER 13

FLUIDIZED BED BOILERS

13-1. Fluidized bed boilers.

13-2. Types of fluidized bed boilers.

through the first and into the second and third genera-

There is no unique design. An industrial fluidized bed

tion of development. Fluidized bed technology is not

boiler could assume several possible configurations

new but has been revived in this country because of

depending on such factors as bed pressure, the choice

fuel costs and the availability of poor quality fuels.

between natural or assisted circulation, the gas velocity

Commercial and industrial power plants now have a

in the bed, fuel and air distribution systems, bed design

third type of solid fuel boiler to consider for steam

and method of achieving high carbon utilization and

requirements. Economics, fuel pricing, availability of

control of sulfur dioxide.

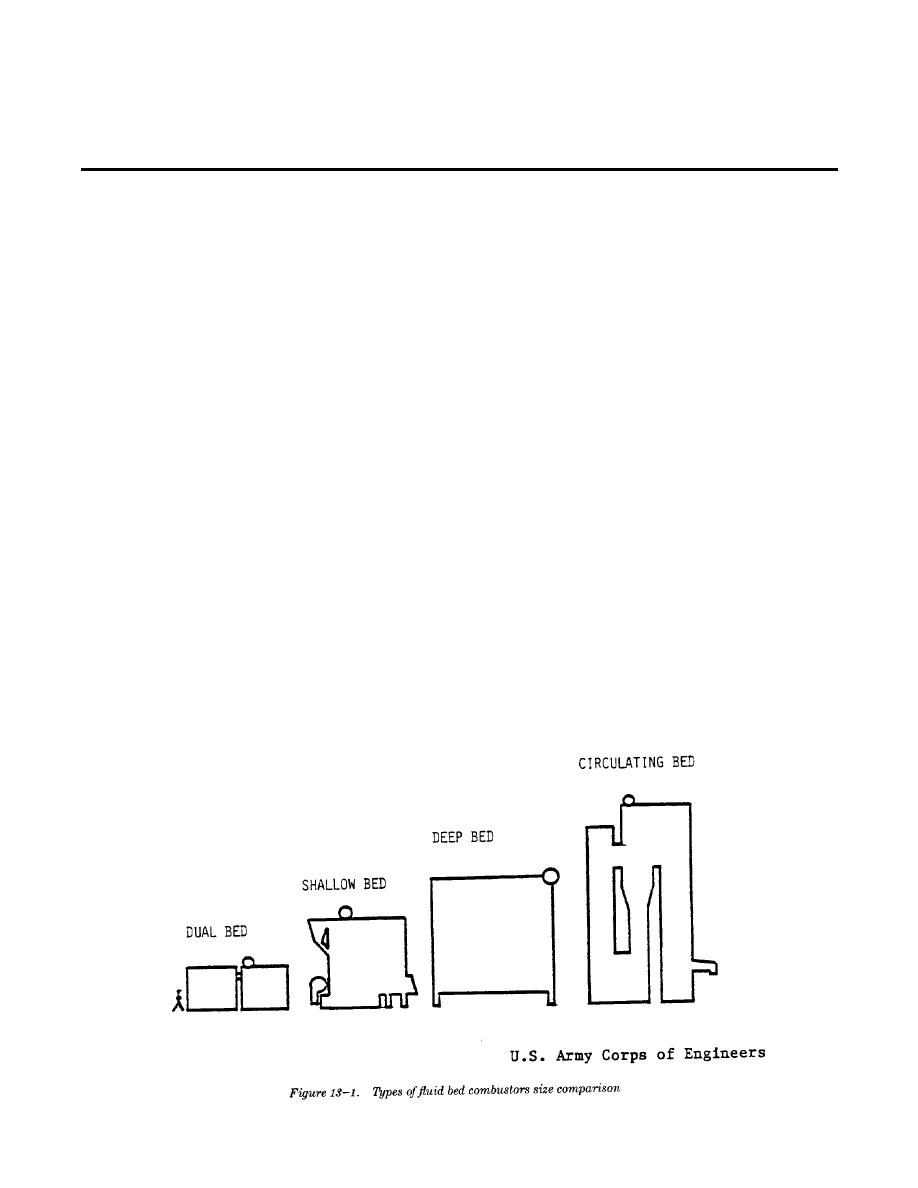

b. There are four types which will be given consider-

low grade fuels and environmental considerations have

made the fluidized bed boiler a viable option to

ation for control of sulfur dioxide and nitrogen oxide

evaluate along with the stoker or pulverized coal fired

emissions. These are shown in figure 13-1 and size is

units. The units can with care be designed to burn a

also compared for a 50 million Btu/hour heat imput

number of fuels including low grade coals, lignite, coal

unit.

c. The types can further be demonstrated by com-

mine wastes (culm), refinery gas, woodwastes, waste

solvents, sludge, etc.

paring them as stationary fluid bed (bubbling bed) or

circulating bed designs. To determine this type, the

burn high sulfur coal and meet environmental require-

relationship between the gas velocity and the differen-

ments without the use of scrubbers. The mixture of

tial pressure in the fluidized bed must be established.

fuel and limestone is injected in such a way that the

Figure 13-2 shows this relationship for various bed

fuel and limestone are distributed across the bed. The

designs.

d. The fluidized bed is a system in which the air

fuel and limestone are kept in turbulent motion by

upward air flow from the bottom of the furnace. The

distributed by a grid or distribution plate, is blown

furnace combustion takes place at about 1550 degrees

through the bed solids developing a "fluidized con-

Fahrenheit to 1750 degrees Fahrenheit. Control of

dition." Fluidization depends largely on the particle size

sulfur dioxide and nitrogen oxide emissions in the

and the air velocity. At low air velocities, a dense

combustion chamber without the need for additional

defined bed surface forms and is usually called a bub-

control equipment is one of the major advantages over

bling fluidized bed. With higher air velocities, the bed

conventional boilers.

13-1

Previous Page

Previous Page