TM 5-805-4/AFJMAN 32-1090

they are not inadvertently short-circuiting the

integral concrete inertia block. (Unless specified

spring mounts.

otherwise, all concrete referred to in this manual

should have a density of at least 140 to 150 lb/ft.3.)

(b) All building trash should be removed

from under the isolated base of the equipment.

(1) The length and the width of the inertia

Loose pieces of grout, 2x4s, nuts, bolts, soft drink

block should be at least 30 percent greater than

bottles, beer cans, welding rods, pipes, and pipe

the length and width of the supported equipment.

couplings left under an equipment base can short-

(2) Mounting brackets for stable steel springs

circuit the isolation mounts. It is recommended

should be located off the sides of the inertia block

that a 2 inch to 4 inch clearances be provided

at or near the height of the vertical center-of-

under all isolated equipment in order to facilitate

gravity of the combined completely assembled

inspection and removal of trash from under the

equipment and concrete block. If necessary, curbs

base.

or pedestals should be used under the base of the

(c) For many equipment installations, there

steel springs in order to bring the top of the loaded

is no need to bolt down the isolation mounts to the

springs up to the center-of-gravity position. As an

floor because the smooth operation of the machine

alternative, the lower portion of the concrete iner-

and the weight of the complete assembly keep the

tia block can be lowered into a pit or cavity in the

system from moving. For some systems, however,

floor so that the steel springs will not have to be

it may be necessary to restrain the equipment

mounted on curbs or pedestals. In any event, the

from "creeping" across the floor. In these situa-

clearance between the floor (or all the surfaces of

tions, it is imperative that the hold-down bolts not

the pit) and the concrete inertia block shall be at

short circuit the pads. A suggested restraining

least 4 inches, and provision should be allowed to

arrangement is illustrated in figure 8-1. Simpler

check this clearance at all points under the block.

versions can be devised.

(3) Floor slab thickness. It is assumed that

(d) For buildings located in earthquake-

MER upper floor slabs will be constructed of dense

concrete of 140-150 lb/ft.3 density, or, if lighter

prone areas, the isolation mounts should contain

snubbers or motion-limiting devices that restrain

concrete is used, the thickness will be increased to

the equipment against unusual amounts of move-

provide the equivalent total mass of the specified

ment. These snubbers should be set to provide

floor. For large MERs containing arrays of large

adequate free movement for normal equipment

and heavy equipment, it is assumed that the floor

operation. These devices are available from most

slab thickness will be in the range of 8 to 12

suppliers of isolator equipment.

inches, with the greater thicknesses required by

b. Type I mounting assembly. The specified

the greater floor loads. For smaller MERs contain-

equipment should be mounted rigidly on a large

ing smaller collections of lighter weight but typi-

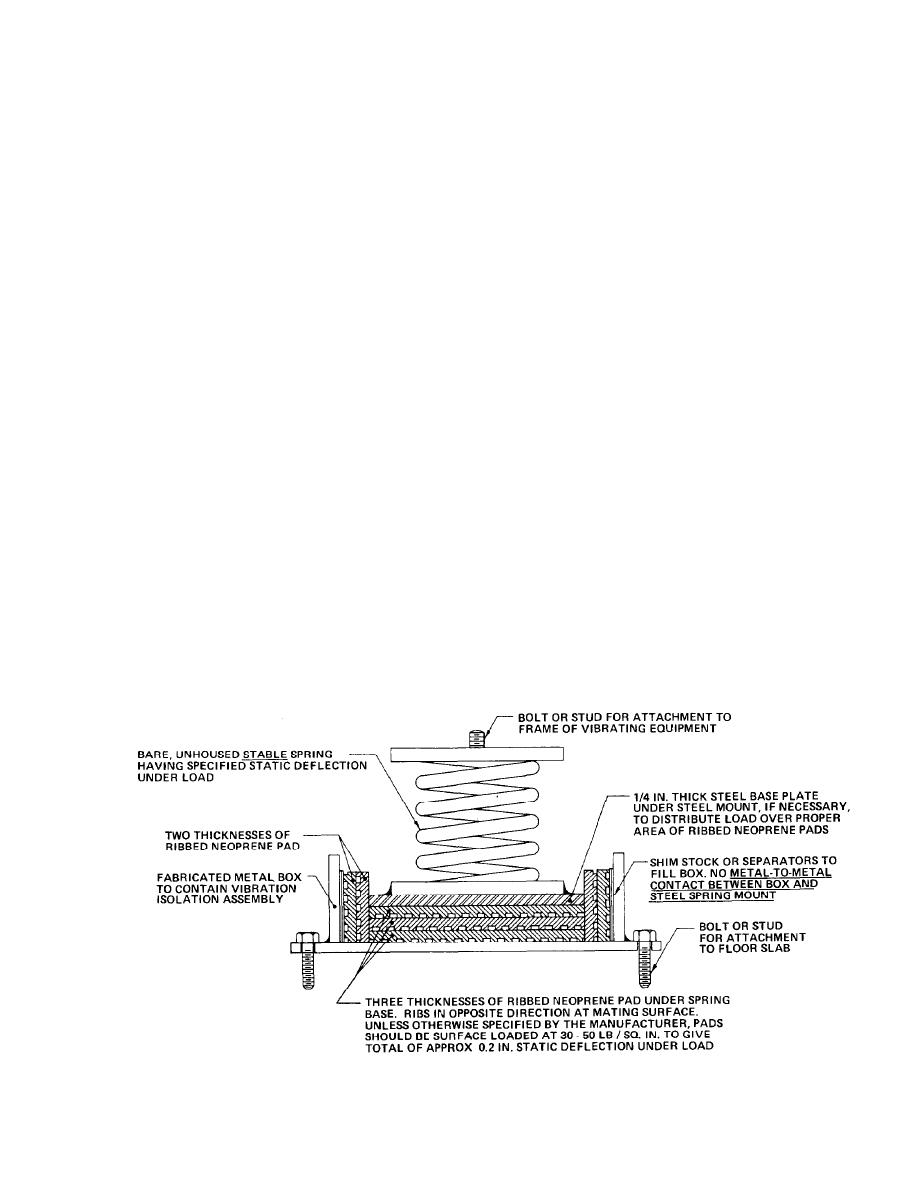

Figure 8-1. Suggested Arrangement of Ribbed Neoprene Pads for Providing Resilient Lateral Restraint to a Spring Mount.

8-4

Previous Page

Previous Page