TM 5-805-4/AFJMAN 32-1090

manufacturer for the particular densities or duro-

there is an acoustically critical area immediately

meters involved. In general, most of these pads are

below the cooling tower (or within about 25 feet

horizontally on the floor immediately under the

intended for load rates of 30 to 60 psi, and if they

are underloaded (for example, at less than about

tower). It is necessary to provide limit stops on

10 psi), they will not. be performing at their

these springs to limit movement of the tower when

maximum effectiveness.

it is emptied and to provide limited movement

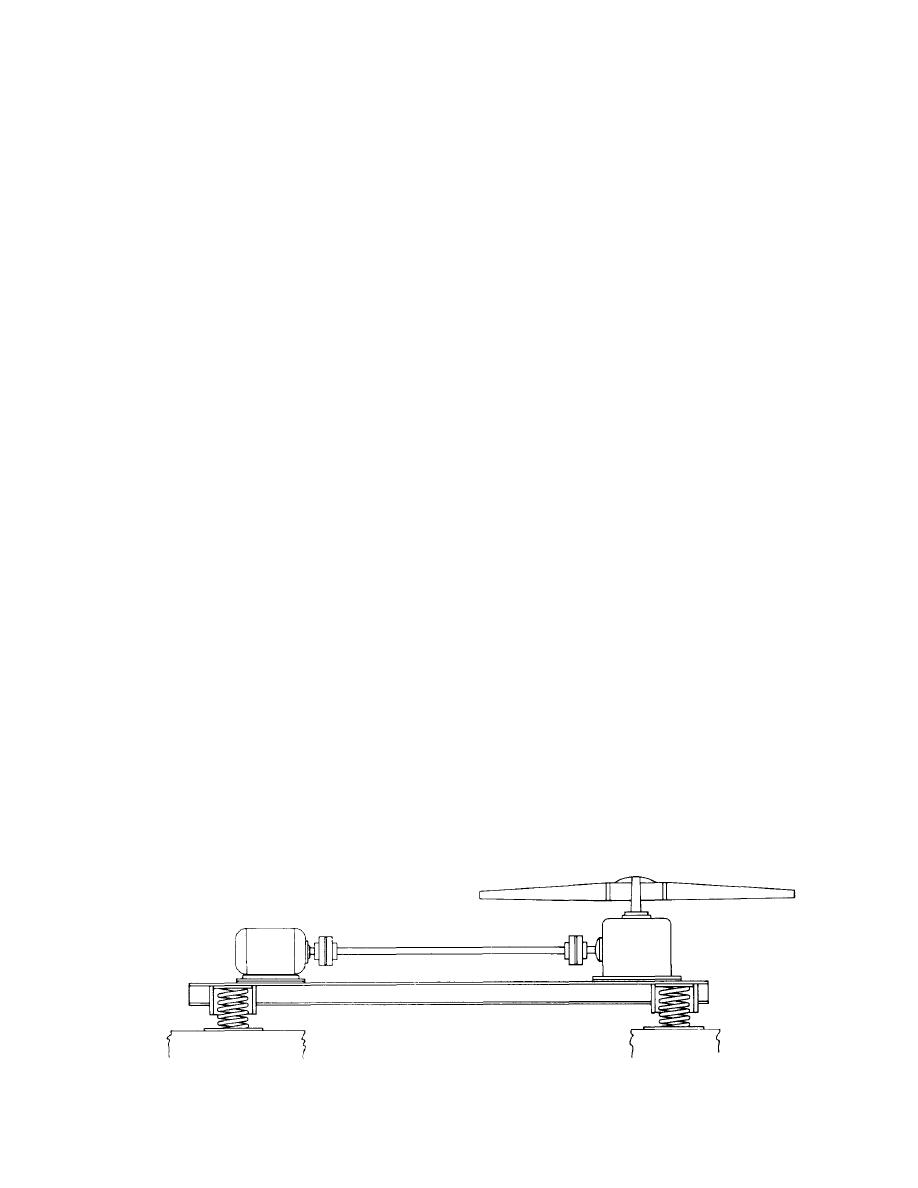

f. Type V mounting assembly (for propeller-type

under wind load.

(4) Pad materials, when used, should not be

cooling towers located on roof decks of large

short-circuited by bolts or rigid connections. A

buildings may produce serious vibration in their

schematic of an acceptable clamping arrangement

buildings if adequate vibration isolation is not

for pad mounts is shown in figure 8-3. Cooling

provided. In extreme cases, the vibration may be

tower piping should be vibration-isolated in accord-

evident two or three floors below the cooling

ance with suggestions given for piping.

towers.

8-4. Tables Of Recommended Vibration Isola-

(1) It is recommended that the motor, drive

tion Details.

shaft, gear reducer, and propeller be mounted as

a. Table format. A common format is used for

rigidly as possible on a "unitized" structural sup-

port and that this entire assembly be isolated from

all the tables that summarize the recommended

the remainder of the tower with stable steel

vibration isolation details for the various types of

springs in accordance with table 8-8. Adequate

equipment. A brief description of the format is

clearance between the propeller tips and the cool-

given here.

(1) Equipment conditions. The three columns

ing tower shroud should be provided to allow for

starting and stopping vibrations of the propeller

on the left of the table define the equipment

assembly. Several of the cooling tower manufactur-

conditions covered by the recommendations: loca-

ers provide isolated assemblies as described here.

tion, rating, and speed of the equipment. The

This type of mounting arrangement is shown

rating is given by a power range for some equip-

schematically in figure 8-2.

ment, cooling capacity for some, and heating ca-

(2) In addition, where the cooling tower is

pacity for some. The rating and speed ranges

located on a roof deck directly over an acoustically

generally cover the range of equipment that might

be encountered in a typical building. Subdivisions

critical area, the structureborne waterfall noise

in rating and speed are made to accommodate

may be objectionable; it can be reduced by locating

variations in the isolation. If vibrating equipment

three layers of ribbed or waffle-pattern neoprene

between the base of the cooling tower and the

is supported or hung from an overhead floor slab,

supporting structure of the building. This treat-

immediately beneath an acoustically critical area,

ment is usually not necessary if there is a noncri-

the same degree of vibration isolation should be

tical area immediately under the cooling tower.

provided as is recommended for the location desig-

(3) A single-treatment alternate to the com-

nated as "on upper floor above critical area".

bined two treatments of (1) and (2) above is the

Similarly, if the vibrating equipment is hung from

an overhead floor slab beneath a noncritical area,

isolation of the entire cooling tower assembly on

stable steel springs, also in accordance with table

the same vibration isolation should be provided as

is recommended for the location designated as "on

8-8. The springs should be in series with at least

two layers of ribbed or waffle-pattern neoprene if

upper floor above noncritical area".

Figure 8-2. Schematic of Vibration Isolation Mounting for Fan and Drive-Assembly of Propeller-Type Cooling Tower.

8-6

Previous Page

Previous Page