TM 5-805-4/AFJMAN 32-1090

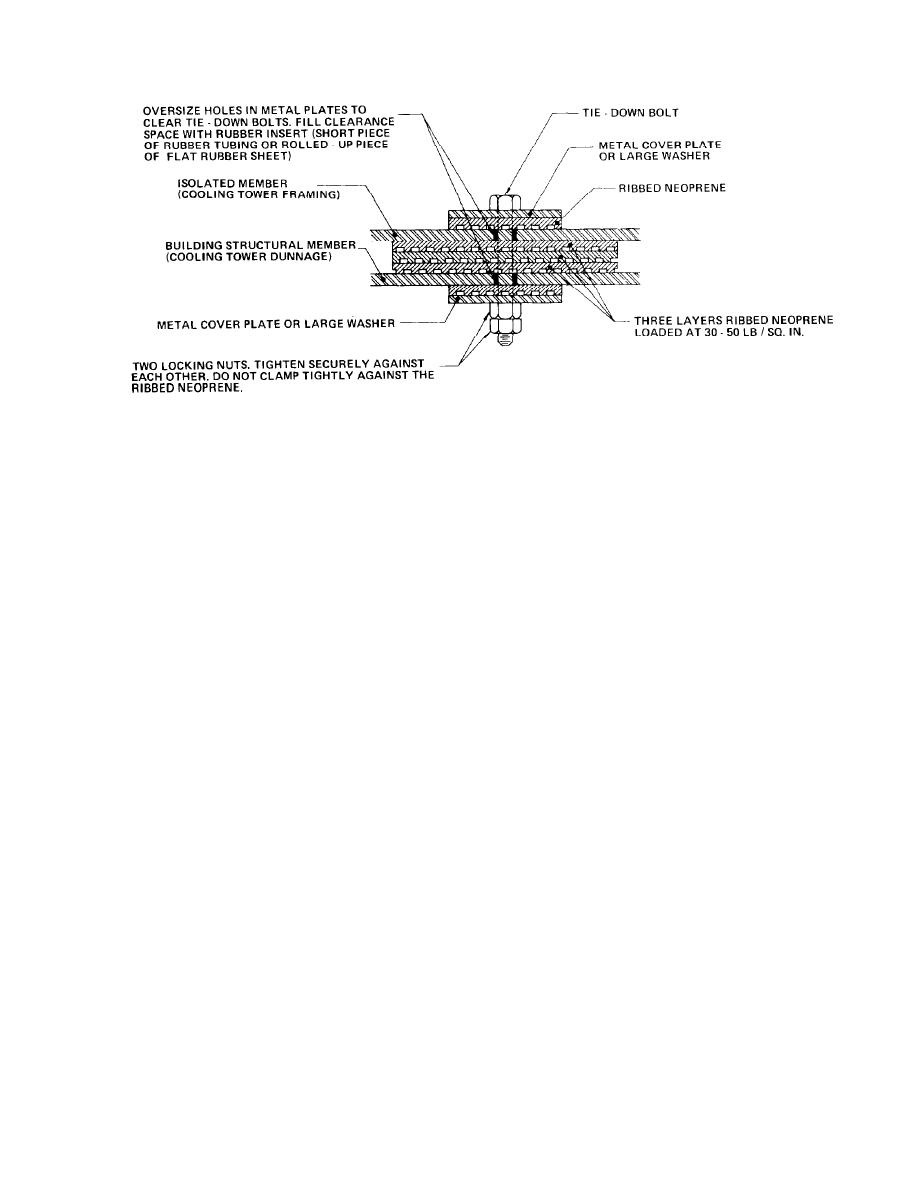

Figure 8-3. Schematic of a Resilient Clamping Arrangement With Ribbed Neoprene Pads.

(2) Mounting recommendations. The three col-

piece of equipment remote from other equipment,

umns on the right of the table summarize three

the recommendations can be relaxed, either by

basic groups of recommendations: Column 1, the

decreasing the static deflection of the mount or by

type of mounting; Column 2, the suggested mini-

decreasing the weight of the inertia block or even

mum ratio of the weight of the inertia block (when

by eliminating the inertia block where a critical

required) to the total weight of all the equipment

area is not involved.

mounted on the inertia block; and Column 3, the

(d) Resilient support of all piping connected

suggested minimum static deflection of the isolator

to vibrating equipment should be in accordance

to be used.

with paragraph 8-5a. This recommendation ap-

(a) When the weight of the inertia block is

plies to the mounting of each piece of vibrating

being considered, the larger weight of the range

equipment, even though it is not repeated below

given should be applied where the nearby critical

for each piece of equipment.

area is very critical, or where the speed of the

b. Centrifugal and axial-flow fans. The recom-

equipment is near the lower limit of the speed

mended vibration isolation mounting for fans are

range given or the rating of the equipment is near

given in table 8-2. Ducts should contain flexible

the upper limit of the rating range. Conversely,

connections at both the inlet and discharge of the

the lower end of the weight range may be applied

fans, and all connections to the fan assembly

where the nearby critical area is less critical, or

should be clearly flexible. The entire assembly

where the speed is near the upper limit of the

should bounce with little restraint when one jumps

speed range or the rating is near the lower limit of

up and down on the unit. Where supply fan

the rating range.

assemblies are located over critical areas, it is

(b) When the static deflection of the isola-

desirable to install the entire inlet casing and all

tors is being considered, these minimum values

auxiliary equipment (coil decks and filter sections)

are keyed to the approximate span of the floor

on floated concrete slabs. The floated slab may

beams; that is, as the floor span increases, the

also serve to reduce airborne noise from the fan

floor deflection increases, and therefore the isola-

inlet area into the floor area below. Large ducts

tor deflection must increase. The specific minimum

(cross-section area over 15 sq feet) that are located

deflection in effect specifies the type of isolator

within about 30 feet of the inlet or discharge of a

that can be used; refer to table 8-1 for the normal

range of static deflection for most isolators. Spe-

large fan (over 20 hp) should be supported from

cific selections should be made from manufactur-

the floor or ceiling with resilient mounts having a

static deflection of at least 1/4 inch.

ers' catalog data.

(c) The recommendations given here assume

c. Reciprocating-compressor refrigeration equip

ment. The recommended vibration isolation for

that a moderate amount of large equipment (say,

more than five or six pieces, totaling more than

this equipment are given in table 8-3. These

about 300 to 600 hp) is located on the MER floor.

recommendations apply also to the drive unit used

with the reciprocating compressor. Pipe connec-

For a smaller array of equipment or for a single

8-7

Previous Page

Previous Page