UFC 3-460-03

21 JANUARY 2003

slowly so pressure surges do not damage the F/S and downstream equipment. The main valve

should open in about 20 seconds.

6.4.4. F/Ss. F/Ss are provided on both the receipt and issue side of Type III system storage tanks.

Issue F/Ss are manifolded together and share the discharge line from the issue pumps. These F/Ss are

rated for 2271 liters per minute (600 gallons per minute). See Chapter 3 for a detailed description.

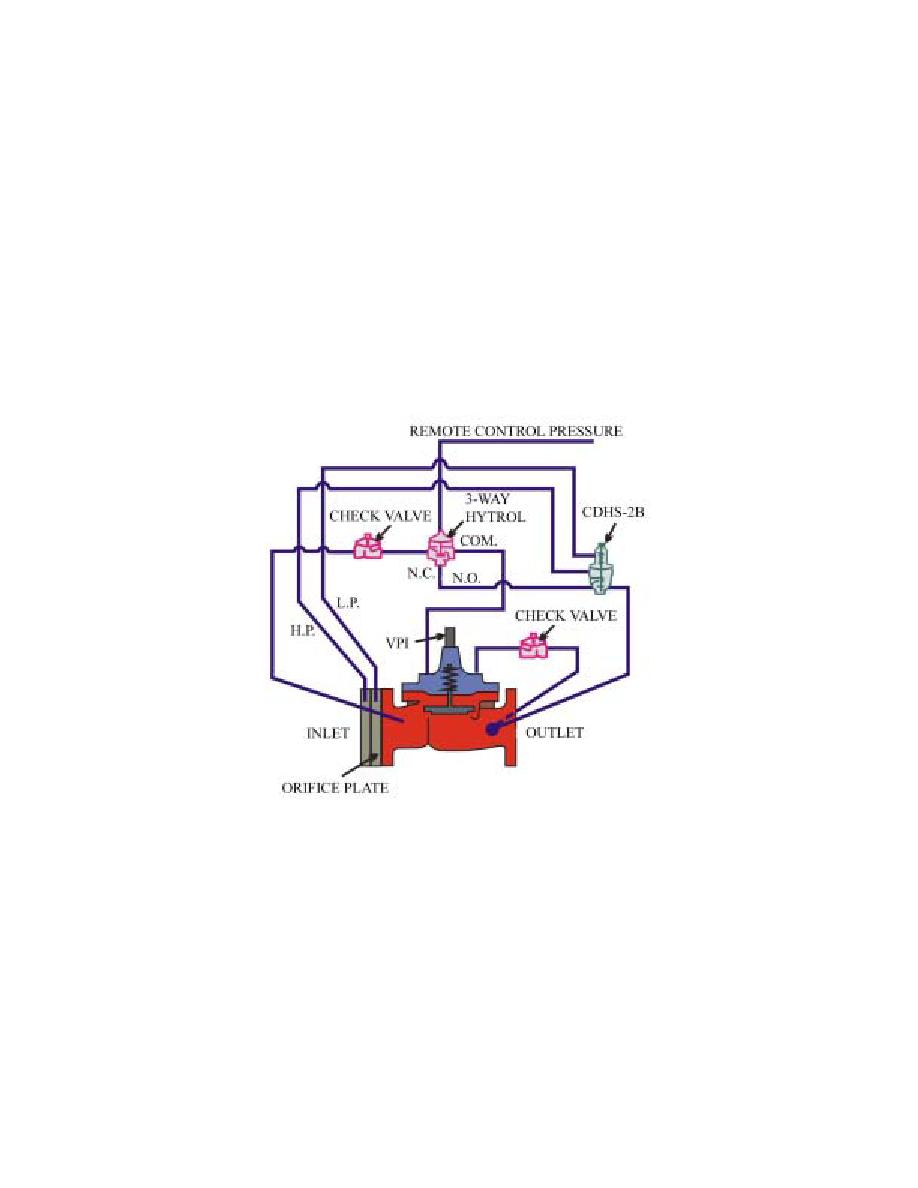

6.4.5. FSCV (41AF-2C).

6.4.5.1. The only difference between the 41AF-2C (Figure 6.4) and the 40AF-2C (Figure 5.3),

used on the Type II system, is the 41AF-2C has check valves installed to prevent reverse flow.

The valve still controls the rate of fuel flow and closes when excess water is detected in the F/S.

Most bases have deactivated the water shut-off feature.

Figure 6.4. F/S Control Valve (41AF-2C).

6.4.5.2. Valve Settings. With one pump running and fuel flowing through one separator, turn the

CDHS-2 adjusting stem clockwise to increase the fuel flow through the valve and

counterclockwise to decrease it. Use the issue DPT to adjust the flow to about 2271 liters per

minute (600 gallons per minute).

6.4.6. Emergency Shut-Off (ESO) Valve (136AF-9B):

6.4.6.1. The ESO valve (Figure 6.5) has two solenoids that are energized when power is on,

enabling the main valve to open when there is fuel flow. Should power fail or an emergency stop

button be pushed, the solenoids will de-energize and the main valve will close within 10 seconds.

The valve also has a thermal relief feature that relieves excess cover chamber pressure back to the

valve inlet. Lastly, a differential relief is used to maintain a relatively constant DP between the

inlet and outlet of the main valve. The ESO valve feature is performed by alternate means for

designs completed since 1999.

58

Previous Page

Previous Page