UFC 3-460-03

21 JANUARY 2003

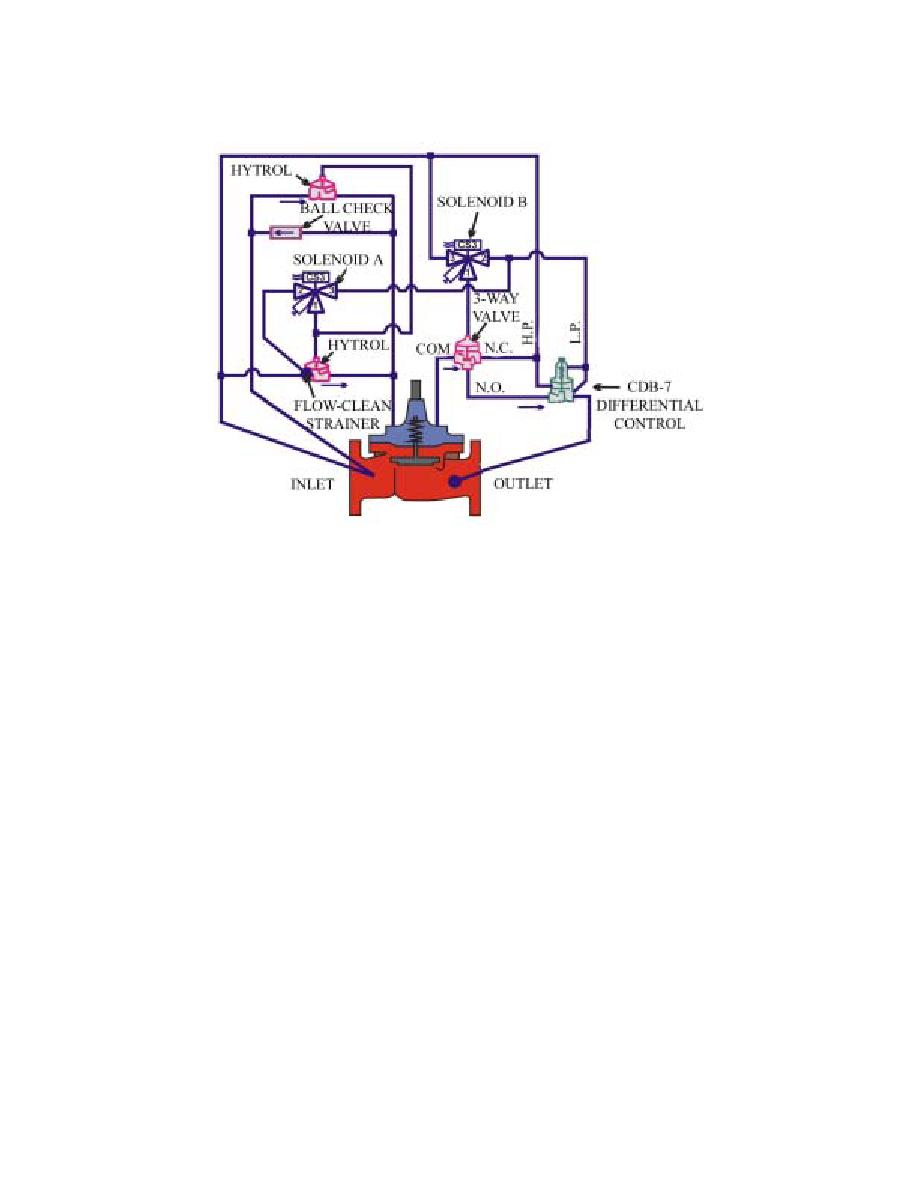

Figure 6.5. ESO Valve (136AF-9B).

6.4.6.2. Valve Setting. Turn the adjusting stem of the CDB-7 clockwise to increase the DP and

counterclockwise to decrease it. The DP should be about 10 psi.

6.4.7. Issue Venturi. The 254-millimeter (10-inch) issue venturi is downstream of the ESO valve and

is typically rated at 9085 liters per minute (2400 gallons per minute). It is similar to an orifice plate

in operation but is much more accurate. It has four 12.7-millimeter connections for piping in the

DPTs. Using signals from the DPTs, the microprocessor measures issue flow with the return-flow

venturi, and controls starting and stopping of the sequential pumps.

6.4.8. Pressure Indication Transmitter (PIT). Two PITs are connected directly to the main issue line

just downstream of the ESO valve. The PITs read system pressure between 0 and 250 psi. The

microprocessor is programmed to call on the lead pump when system pressure drops below 60 psi

and call it off when system pressure reaches a preset pressure between 135 and 175 psi. The

microprocessor uses the 4- to 20-milliampere signals from these two transmitters to turn the lead

pump on or off. This signal is directly proportional to the pressure being measured. Calibrate the

PIT with a manometer; the digital type is recommended. Refer to the manufacturer's instructions for

details.

6.4.9. DPT. DPTs measure DP across the venturi and have displays that express flow in gallons per

minute. There are two DPTs connected to the issue venturi (the range is 0 to 9085 liters per minute

[0 to 2400 gallons per minute]) and four connected to the return venturi. Two of the four are for low

flows with a range of 0 to 379 liters per minute (0 to 100 gallons per minute) and the remaining two

are for high flows with a range of 0 to 3028 liters per minute (0 to 800 gallons per minute). The

microprocessor uses the 4- to 20-milliampere signals from these six transmitters to turn sequential

pumps on or off. This signal is directly proportional to the DP being measured. Calibrate the DPTs

with a manometer; the digital type is recommended. Refer to the manufacturer's instructions for

details.

6.4.10. Hydrant Loop. After leaving the issue venturi, fuel flows through the hydrant loop back to

the operating storage tank. The loop is under the parking apron with a hydrant control pit at each

59

Previous Page

Previous Page