UFC 3-535-01

17 November 2005

L = T x KW

Where:L = Length of cable pulled (in feet)

T = Total tension (in pounds)

K = Coefficient of friction (0.3 for single cables, 0.4 for multiple cables)

W = Weight of all cables being pulled (in pounds/foot)

12-4.6

A dynamometer should be used to monitor the cable tension during

pulling. Alternatively, a contractor may adapt a rope harness properly sized to limit pull

tension. Types and sizes for ropes used in this manner may be found in FAA-C-1391

Table 1. Manufacturer's data on allowable cable pulling tension should always be used.

Any combination of a group of cables to be pulled into a duct must not exceed the sum

of individual allowable tension of each cable plus 15 percent. Typical examples of the

allowable maximum tension for various types of cable are shown in Table 12-4.

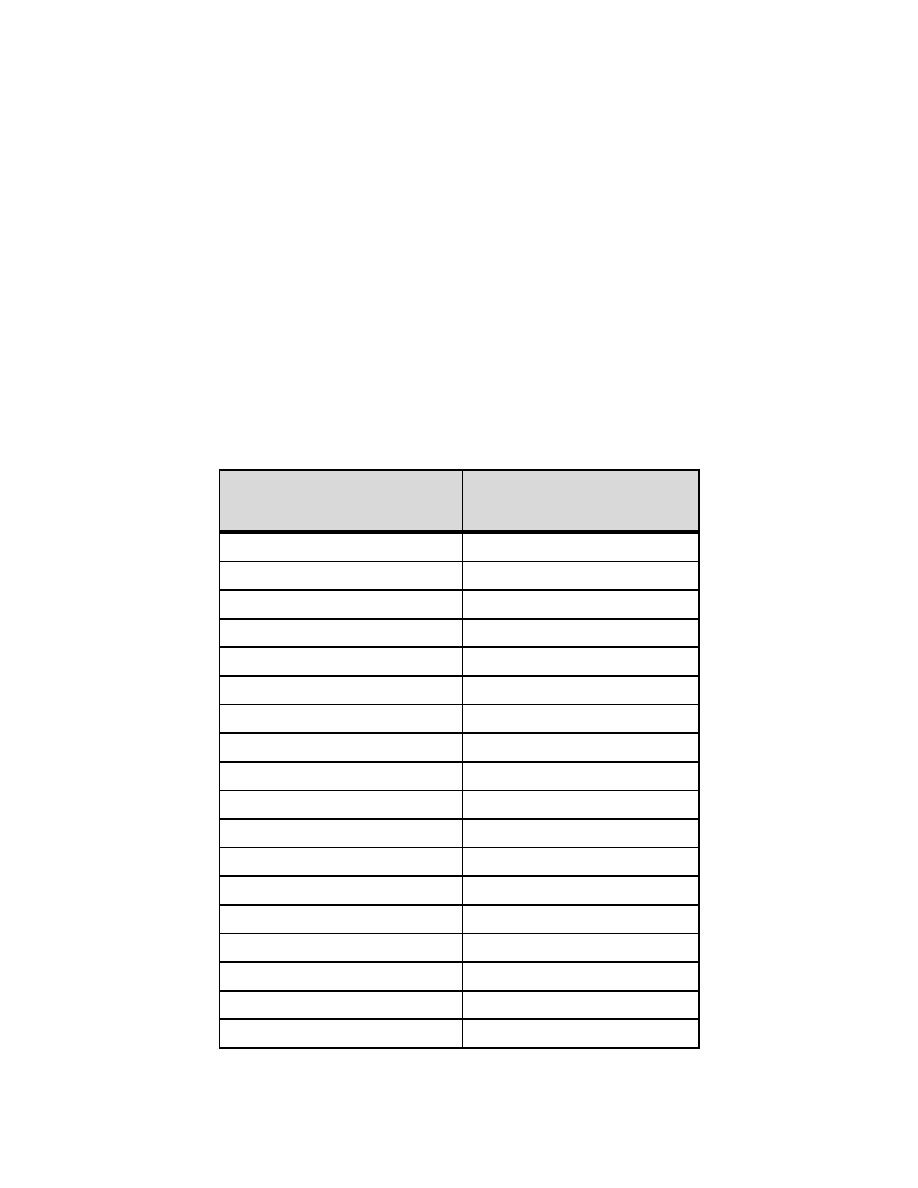

Table 12-4. Maximum Allowable Non-Armored Cable Pulling Tension,

Using Dynamometer

Tension

Cable

Kg (Lb.)

2 1/C #8 solid

125 (275)

3 1/C #8 solid

167 (367)

4 1/C #8 solid

250 (550)

2 1/C #6 stranded

191 (420)

3 1/C #6 stranded

286 (630)

4 1/C #6 stranded

382 (840)

1 2/C #8 stranded

139 (305)

1 3/C #8 stranded

180 (395)

1 4/C #8 stranded

266 (585)

1 2/C #6 stranded

207 (455)

1 3/C #6 stranded

311 (685)

1 4/C #6 stranded

400 (880)

1 6/C #12 stranded

143 (315)

1 12/C #12 stranded

286 (630)

1 12 pair #19 solid

105 (230)

1 25 pair #19 solid

246 (541)

1 50 pair #19 solid

482 (1061)

1 100 pair #19 solid

909 (2000)

178

Previous Page

Previous Page