Design Guide: Band Training Facilities

DG-1110-3-119

March 1983

General Design Programming

noisy NC-40. The largest of the music rooms must be

an opening between two music rooms, then the connec-

quietest, because here musicians who may be dispersed

tion should involve a pair of doors facing each other

over a large area still must hear each other. So must the

across the widest space possible.

audience, if present. With decreasing room size and

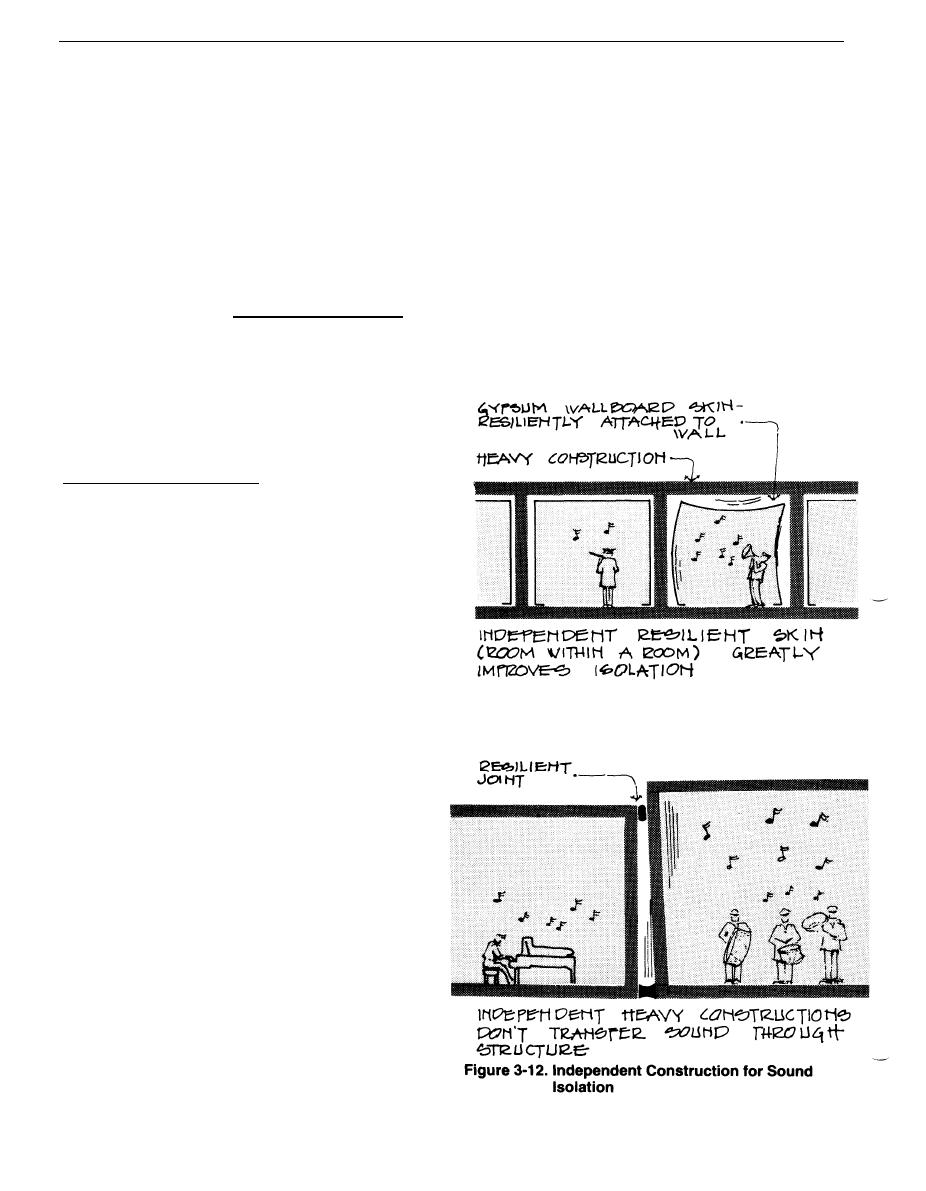

Isolation can be increased further by building an indepen-

reduced occupancy, audibility inherently improves. In the

dent "room" within the heavy walls already constructed, or

smaller rooms, even with the suggested, higher back-

adding another separate masonry wall next to the first

ground noise levels, adequate signal/noise ratios are still

(see Figure 3-12). These added elements must be iso-

retained (background noise will be discussed later).

lated completely in such a way that the vibration of one

barrier will not be passed on to the other. An independent

Table 3-1 Recommended Sound Isolation Criteria

skin of gypsum wallboard or plaster, attached to walls

for Band Training Facilities

and roof with resilient clips, is very effective.

allowable

Factory-made sound modules are an effective means of

noise from

generated

providing smaller practice rooms of good quality, either in

outside

noise

conversions where dependable construction may be

Recording/Audio Control

difficult, or in new construction. They provide light, heat and

Booths

max. NC-25 ---

air supply and all interior finishes. They may also be use-

Main Rehearsal Room

max. NC-25 100 dB

ful for Recording/Audio Control Rooms (see Figure 3-13).

Group Practice Rooms

max. NC-30 95 dB

Individual Practice

Rooms

max. NC-35 90 dB

All other occupied

spaces

max. NC-40 ---

2. Construction Implications. Some types of construction

are inherently more suitable for band facilities. Since sound

is a transmitted vibration, its isolation requires construc-

tions that are not easily set into vibration. Concrete slabs,

solid or sand-filled masonry or concrete walls, and con-

crete roofs are appropriate, because their weight helps stop

low frequency sound. Design consideration should begin

with a massive construction system rather than a lighter

framework that will require elaborate soundproofing later,

to less effect. Continuous metal roof decks and steel frames

are not recommended, because they will transmit vibra-

tion throughout the building, no matter how good the wall

construction.

Rehearsal and practice rooms are best located on grade.

This eliminates the need for double floor constructions,

which would be necessary not only for vertical isolation

(to/from the rooms below), but also to stop sound from

propagating horizontally along the unrestrained upper-floor

slab.

Sound waves travel freely in air, so it is imperative that all

music rooms are sealed boxes, with no air gaps--even

tiny ones--or defects in construction. Partial separations

and semi-open planning are totally inadequate, as are

folding partitions. Flexible acoustic sealants are an essen-

tial part of good acoustical construction. Elaborate layers

of materials are wasted if poor workmanship at the joints

and corners allows air passage. This includes joints where

partitions meet the roof, seals around doors and windows,

and where mechanical and electrical lines penetrate walls.

Doors are the weakest point in the enclosure, and must

always be fully gasketed, unless they are incorporated

into a sound lock (two doors separated by a vestibule). It

is more dependable to install a series of doors with a

sound lock, than to depend on one expensive sound-

insulated door. Gaskets need periodic adjustment, and

misuse can make them ineffective, whereas a sound lock

will always perform its function. If it is necessary to have

3-12

Previous Page

Previous Page