Project Name

Project Number

TEMF

Statement of Work

UFC 4-214-02, 24 Jul 03

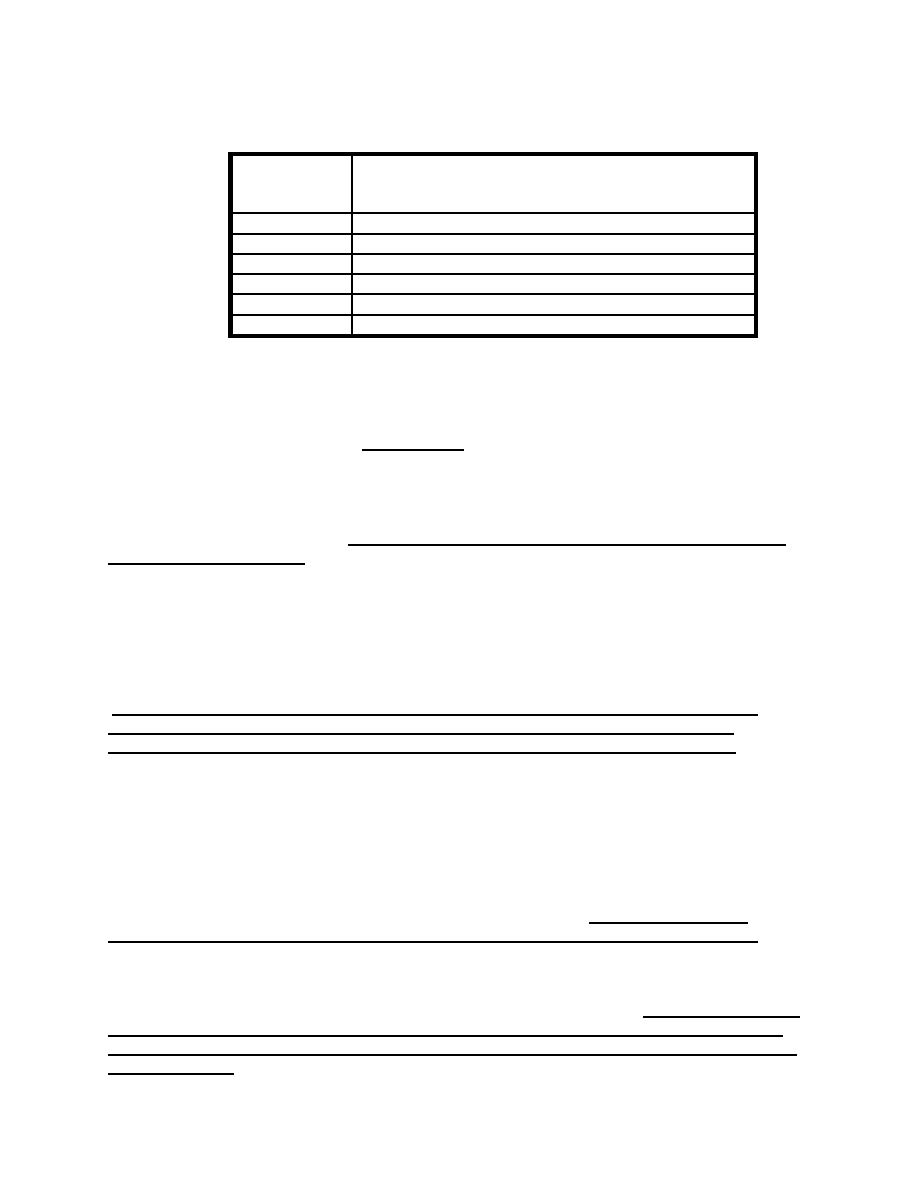

Table 2.A Mechanics Per Repair and Scheduled Maintenance Bay

NUMBER OF TYPE OF ORGANIZATION

MECHANICS

PER BAY

4

TDA Organizations (DOL/DPW)

9

Organizational Maintenance - Non-Engineer

16

Organizational Maintenance - Light Engineer

12

Organizational Maintenance - All Other

12

Direct Support

9

General Support

]

Spaces are as follows:

Repair Bays. Provide [insert number]; net area shall be 192 m2 each. Bay size

2-2.1.1

shall be 9800 mm wide (column centerline to column centerline) x 19 600 mm deep (exterior

face of column to exterior face of column). Refer to Figure 2.1 for diagram of Repair Bay floor

plan. Bay height shall be as required to allow minimum bridge crane hook cradle height stated

below. Provide 7400 mm wide x 4300 mm high overhead doors at front and rear exterior walls

to allow drive-through capability [modify if cold weather variation (vehicle corridor and vehicle

warm-up vestibule) is used]. Provide daylighting through use of metal windows or translucent

wall panels at exterior wall area above vehicle doors. Partitions between adjacent repair bays

are not required.

2-2.1.1.1 Function: repair of wheeled vehicles, tracked vehicles, tank turrets and chassis,

infantry fighting vehicles, construction equipment, missile launchers, towed howitzers, self-

propelled artillery, and large power generation equipment. Bays will also be used for

metalworking, [welding, generator repair, front-end alignment, glass repair, and painting].

[Review TOE/TDA and FPS; edit previous sentence to reflect activities authorized for this

project. Front-end alignment, glass repair and painting are usually authorized only for

Directorates of Logistics (DOL) and Directorates of Public Works (DPW) organizations].

2-2.1.1.2 Adjacency requirements: Adjacent to other repair bays, and/or circulation bay(s)

and/or scheduled maintenance bay(s). Adjacent to hardstand vehicle access aisles. A

maximum of eight bays may be located on one side of the building core.

2-2.1.1.3 Furnishings/Fixtures/Equipment: All bays shall be provided with a traveling bridge

crane with full bay coverage: [provide a 32 metric ton capacity, top running bridge crane, with

separate crane support structure, for 50 percent (or one wing) of repair bays. 32metric ton hook

cradle height shall be 7600 mm above highest point of bay floor.] [32 metric ton crane is

authorized for 50 percent of repair bays in DOL, DPW, and general support level facilities]

provide a 7 metric ton capacity, under-running bridge crane at all [other] repair and scheduled

maintenance bays. 7 metric ton crane hook cradle height shall be 6000 mm above highest point

of bay floor. Provide vehicle exhaust evacuation system at each bay. Provide minimum of 4

compressed air outlets per bay. [Provide bulk POL dispensing system.] [Coordinate with user.

Dispensing systems are personal property fixed (PPF); they are not MCA funded, but can be

provided as part of construction contract when funded by the user, and identified as a line item

on form DD 1391]. Provide one hose bibb per bay, mounted on exterior wall between doors,

1000 mm above floor. [Design space for, and provide electrical power and compressed air

SOW-6

Previous Page

Previous Page