TM 5-628/AFR 91-44

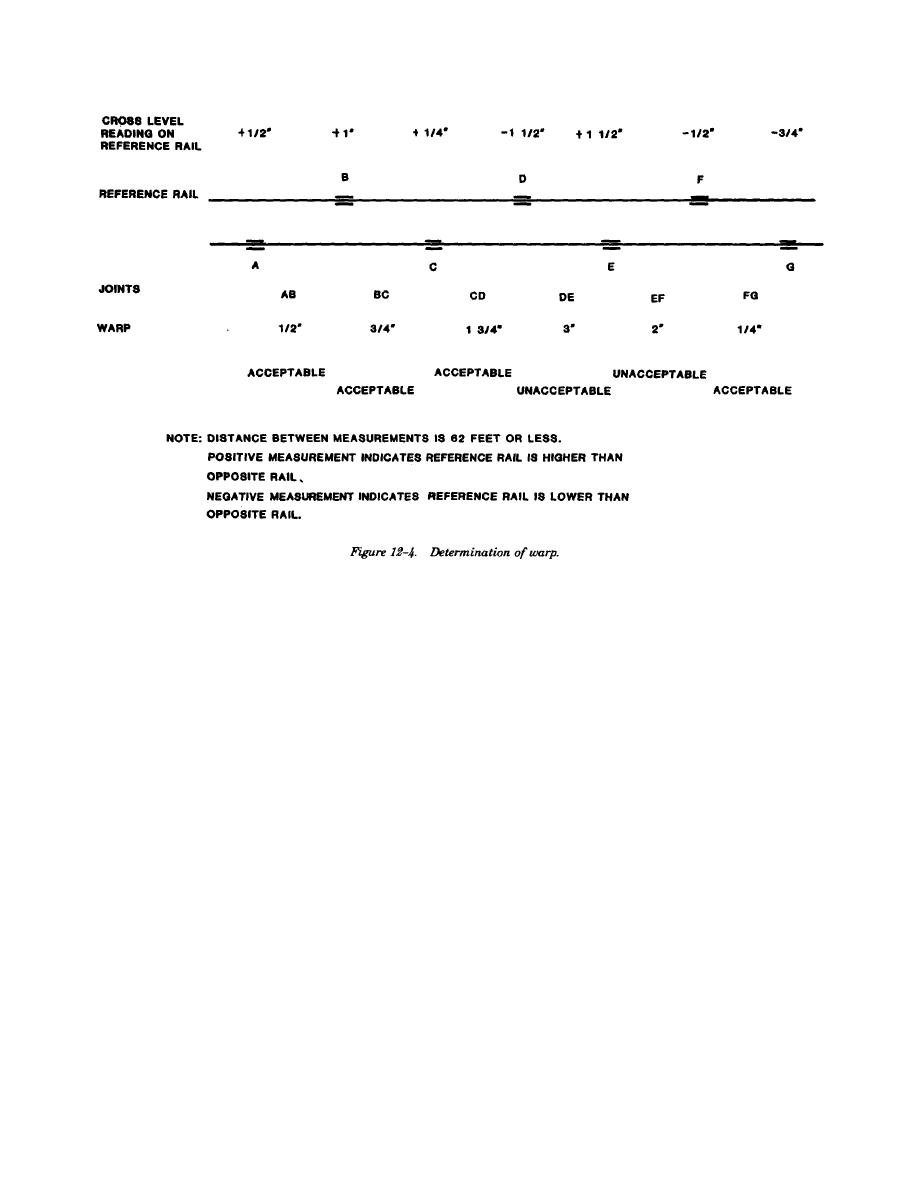

b. Designated warp. The designated warp on

(0.625) inch below the top of the rail head. The

both tangent and curved track is zero.

alinement measurement is the distance in inches

c. Allowable deviations and operating restric-

from the midpoint of the stringline to the gage side

tions.

of the line rail. It is measured at right angles to the

(1) At any location where the warp exceeds

stringline.

c. Designated alinement. For tangent track the

1 (1.75) inches, operations shall not exceed 10

mph.

designated alinement is zero. For curved track the

(2) At any location where the warp exceeds

designated alinement is the degree of curvature. In

2 (2.50) inches, operations shall not exceed 5

spirals the change in curvature will be at a uniform

mph.

rate.

d. Curvature measurement. On curves, 1 inch

(3) Operations shall not be permitted over

any location where the measured warp is greater

distance from the stringline to the line rail equals

than 3 (3.00) inches.

approximately 1 degree of curvature, as shown in

figure 12-5. If the degree of curvature is not

known, it can be determined as follows:

12-6. Alinement.

(1) Beginning at a point near the center of

a. Definition. Alinement is the relative position

the curve, mark at least two stations spaced 31 feet

of the rails in a horizontal plane.

apart in both directions along the line rail.

b. Measurement. Alinement is measured at the

midpoint of a 62-foot stringline stretched along the

gage side of the line rail at a distance of %

12-4

Previous Page

Previous Page