TM 5-628/AFR 91-44

CHAPTER 12

TRACK GEOMETRY

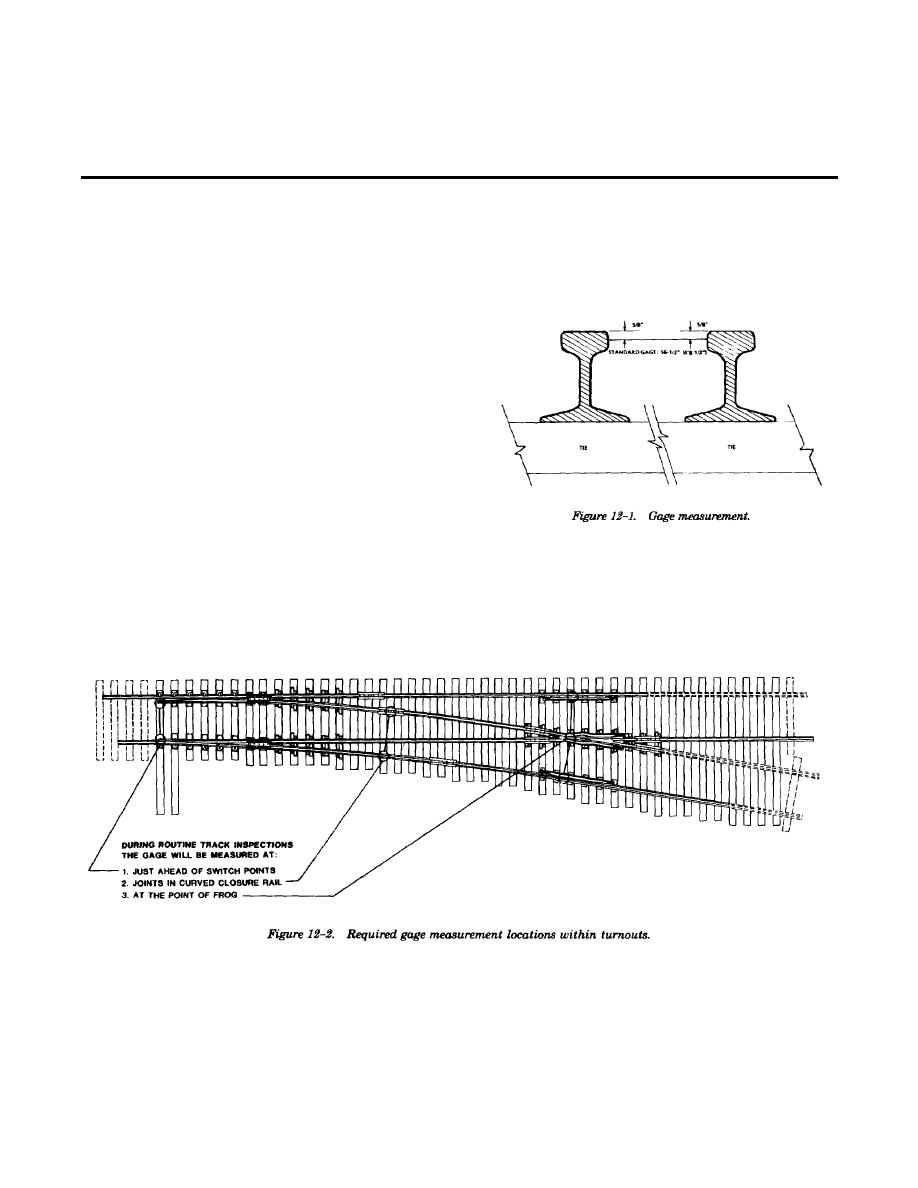

plane % (0.625) inch below the top surface of the

2-1. General.

rail head, as shown in figure 12-1. Gage measure-

a. One rail shall be designated as the line rail.

ments shall include any evidence of lateral move-

The alignment of the track is established by this

ment under load.

rail. Either rail may be used as the line rail on

tangent track so long as the same rail is used for

the entire length of the tangent. The outside rail in

a curve is always the line rail.

b. In curves, the inside rail is designated as the

grade rail. The grade rail is the reference from

which superelevation is applied to the outside rail

of the curve.

c. During routine track inspections, track

geometry measurements shall be taken as a

minimum at the following locations:

(1) Wherever there are visual indications of

track geometry deviations.

(2) Wherever track geometry deviations

were previously detected, unless the deviation has

been corrected.

b. Measurement locations. During routine

(3) Other locations as specified in this

track inspections gage shall be measured at the

chapter.

following locations:

(1) In turnouts, just ahead of switch points.

12-2. Gage.

(See fig 12-2)

a. Definition. Gage is the distance between the

two rails, measured at right angles to the rails in a

(2) In turnouts, at the joints in curved

(5) Wherever wear marks on a tie indicate

closure rails. (See fig 12--2)

lateral tie plate movement.

(3) At the point of frog on both sides of

(6) At locations where ties are badly

turnouts and rail crossings. (See fig 12-2)

skewed.

(4) Wherever there is a dark streak running

(7) In road crossings.

along the field side of the top surface of the rail

(8) In extremely sharp curves (12 degrees or

head.

greater) gage shall be measured in at least three

well-spaced locations within the curve.

12-1

Previous Page

Previous Page