TM 5-805-4/AFJMAN 32-1090

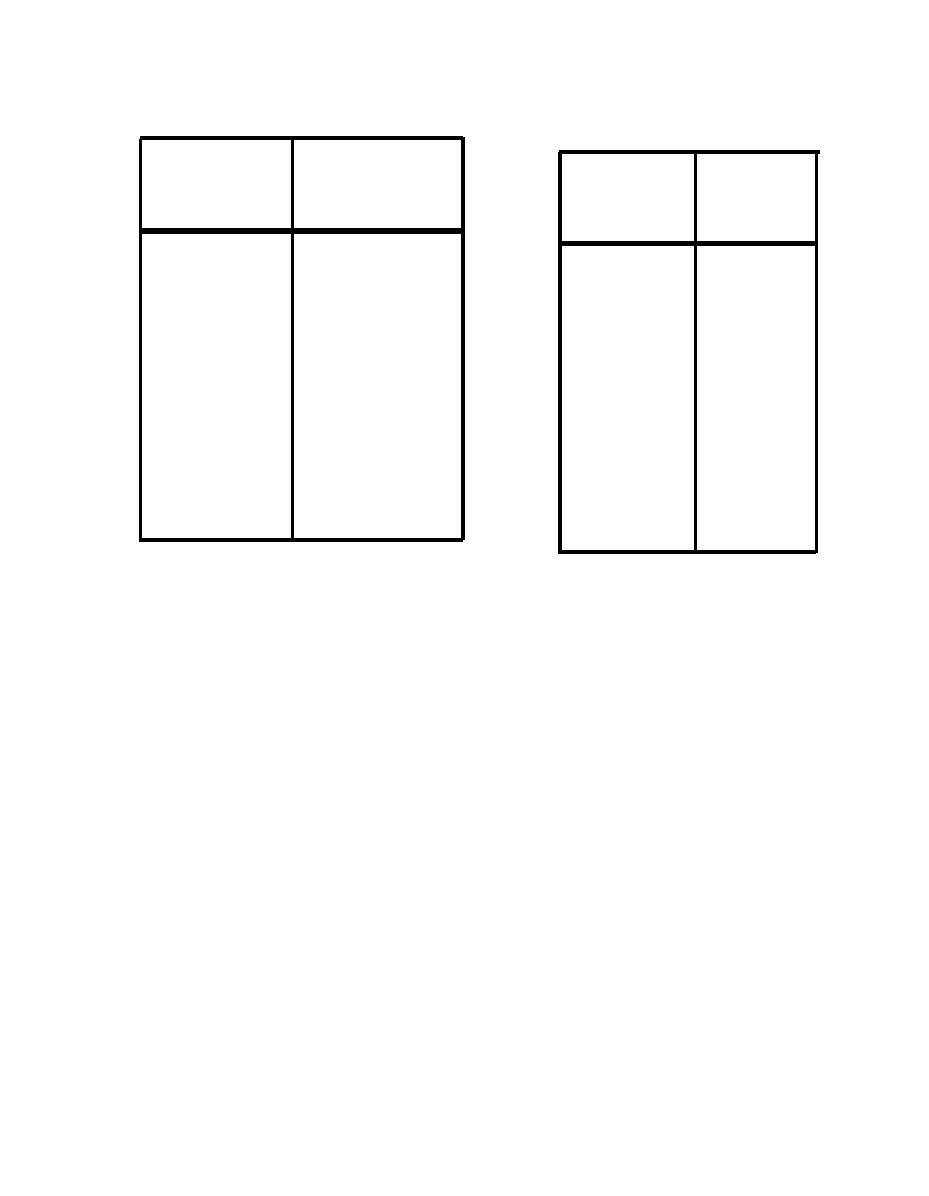

Table C-5. Sound Pressure Levels (in dB at 3-ft. Distance From

Table C-6. Sound Pressure Levels (in dB at 3-ft. Distance) for

the Front) for Boilers.

High-Pressure Thermally Insulated Steam Valves and Nearby

Piping.

Octave

Sound Pressure

Octave

Sound

Level, dB

Pressure

Band

Level

5 0 - 2 0 0 0 BHP

(Hz)

(Hz)

(dB)

90

31

70

31

90

63

70

63

90

125

70

125

87

250

70

250

84

500

75

500

82

1000

80

1000

80

2000

85

2000

76

4000

90

4000

70

8000

90

8000

88

A-weighted,

A-weighted,

dB(A)

94

dB(A)

desirable to obtain from the manufacturer actual

be expressed in different ways: sq. ft. of heating

measured noise levels for all directions of interest,

surface, BTU/hour, lb of steam/hour, or bhp boiler

but if these data are not forthcoming, it is essen-

horsepower). To a first approximation, some of

tial to be able to approximate the directional

these terms are interrelated as follows:

pattern of the cooling tower noise. For aid in

33,500 BTU/hour = 1 bhp

identification, four general types of cooling towers

33 lb of steam/hour = 1 bhp.

are sketched in figure C-3: A.) The centrifugal-fan

In the manual, all ratings have been reduced to

blow-through type; B.) The axial-flow blow-through

equivalent bhp.

type (with the fan or fans located on a side wall);

C.) The induced-draft propeller type; and D.) The

C-9. Steam Valves

"underflow" forced draft propeller type (with the

Estimated noise levels are given in table C-6 for a

fan located under the assembly).

a. Sound power level data. Sound power level

typical thermally insulated steam pipe and valve.

d a t a are given for both propeller-type and

Even though the noise is generated near the

centrigual-fan cooling towers.

orifice of the valve, the pipes on either side of the

(1) Propeller-type cooling tower. The approxi-

valve radiate a large part of the total noise energy

mate overall and A-weighted sound power levels of

that is radiated. Hence, the pipe is considered,

propeller-type cooling towers are given by equa-

along with the valve, as a part of the noise source.

tions C-1 and C-2, respectively: for overall PWL

Valve noise is largely determined by valve type

(propeller-type),

and design, pressure and flow conditions, and pipe

Lw = 95 + 10 log (fan hp),

(eq C-1)

wall thickness. Some valve manufacturers can

and for A-weighted PWL,

provide valve noise estimated for their products.

(eq C-2)

Lwa = 86 + 10 log (fan hp),

C-10. Cooling Towers and Evaporative Con-

w h e r e "fan hp" is the nameplate horsepower

densers.

rating of the motor that drives the fan. Octave

band PWLs can be obtained by subtracting the

The generalizations drawn here may not apply

values of table C-7 from the overall PWL.

exactly to all cooling towers and condensers, but

(2) Centrifugal fan cooling tower. The approxi-

the data are useful for laying out cooling towers

mate overall and A-weighted sound power levels of

and their possible noise control treatments. It is

C-5

Previous Page

Previous Page