TM S-805-4/AFJMAN 32-1090

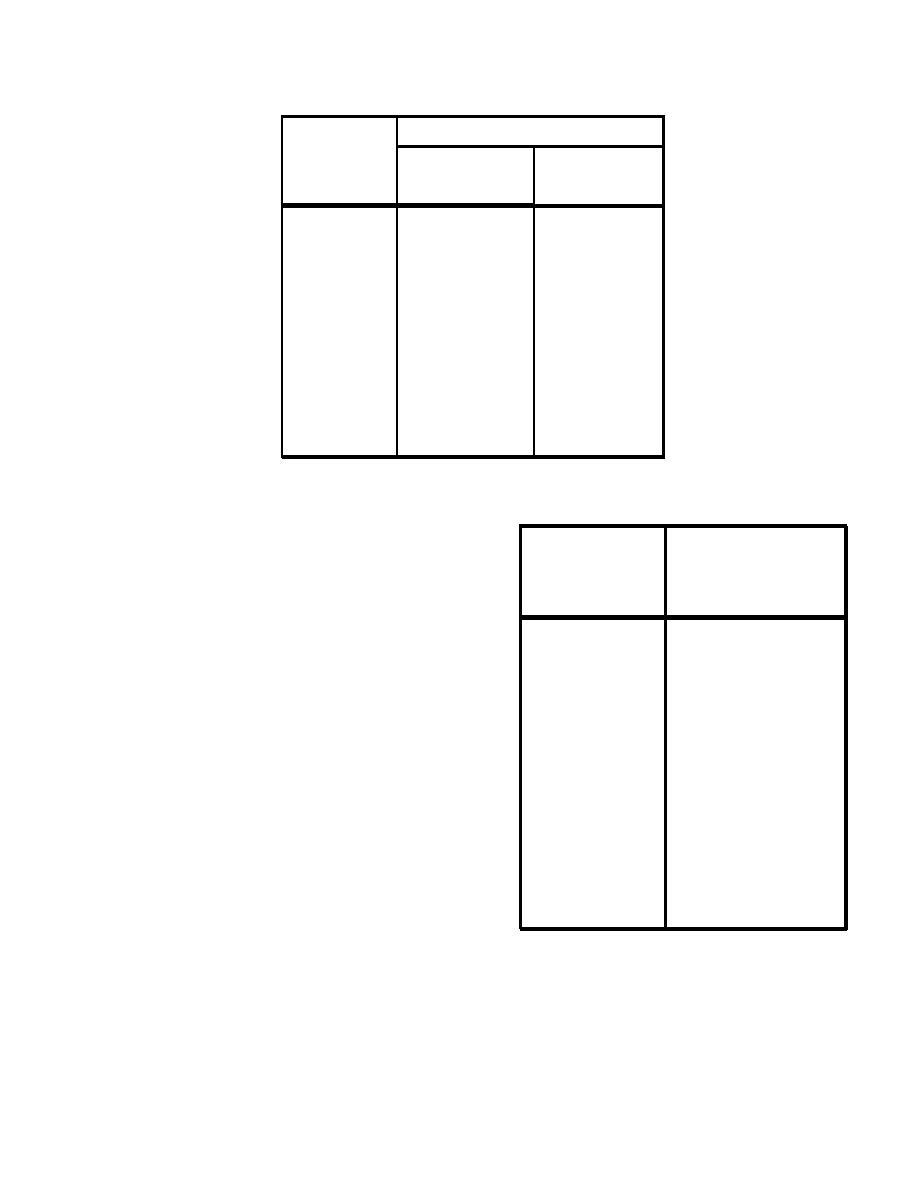

Table C-3. Sound Pressure Levels (in dB at 3-ft. Distance) for Packaged Chillers With Centrifgal Compressors.

Sound Pressure Level, dB

Octave

Cooling

Cooling

Band

Capacity Under

Capacity 500

Tons or More

500 Tons

(Hz)

31

92

92

63

93

93

125

94

94

250

95

95

500

91

93

1000

91

98

2000

91

98

4000

87

93

8000

80

87

A-weighted,

97

103

dB(A)

Table C-4. Sound Pressure Levels (in dB at 3-ft. Distance) for

each component making up the assembly. Compres-

Absorption Machines.

sor noise levels should be taken from the packaged

chiller data. Sound level data for the drive units

(motors, gears, steam turbines) should be taken

Octave

Sound Pressure

from the appropriate tables in the manual or

Level, dB

obtained from the manufacturers. Decibel addition

Band

should be used to determine each octave band sum

All Sizes

(Hz)

from the octave band levels of the various compo-

nents. The acoustic center should be assumed to be

31

80

at the approximate geometric center of the assem-

63

82

bly, and distances should be extrapolated from that

point. For very close distances (such as 2 to 3 feet)

125

82

to each component, assume the total sound levels

250

82

apply all around the equipment at distances of 3

feet from the approximate geometric centers of each

500

82

component, although this assumption will not pro-

1000

81

vide exact close-in sound levels.

2000

78

C-7. Absorption Machines.

4000

75

These units are normally masked by other noise in

a mechanical equipment room. The machine usu-

8000

70

ally includes one or two small pumps; steam flow

noise or steam valve noise may also be present.

86

A-weighted,

The 3 foot distance SPLs for most absorption

dB(A)

machines used in refrigeration systems for build-

ings are given in table C-4.

concern, the distance should always be taken from

C-8. Boilers.

the front surface of the boiler. Noise levels are

much lower off the side and rear of the typical

a. Noise data. The estimated noise levels given

boiler. The wise variety of blower assemblies, air

in table C-5 are believed applicable for all boilers,

and fuel inlet arrangements, burners, and combus-

although some units will exceed these values and,

tion chambers provides such variability in the

certainly, many units will be much lower than

noise data that it is impossible simply to correlate

these values. These 3 foot noise levels apply to the

noise with heating capacity.

front of the boiler, so when other distances are of

C-4

Previous Page

Previous Page