TM 5-805-4/AFJMAN 32-1090

the form of "stiffness" values. For example, a

even pads of cork and felt when operating in their

proper load range.

stiffness of 400 lb/in. means that a 400 lb load will

c. Application suggestions. Table B-3 provides a

produce a 1 inch static deflection, or that an 800 lb

suggested schedule for achieving various degrees

load will produce a 2 inch deflection, assuming that

of vibration isolation in normal construction. The

the mount has freedom to deflect a full 2 inches.

table is based on the transmissibility curve, but

b. Natural frequency of a mount. The natural

suggests operating ranges of the ratio of driving

frequency of steel springs and most other vibration

frequency to natural frequency. The terms "low,"

isolation materials can be calculated approxi-

"fair," and "high" are merely word descriptors,

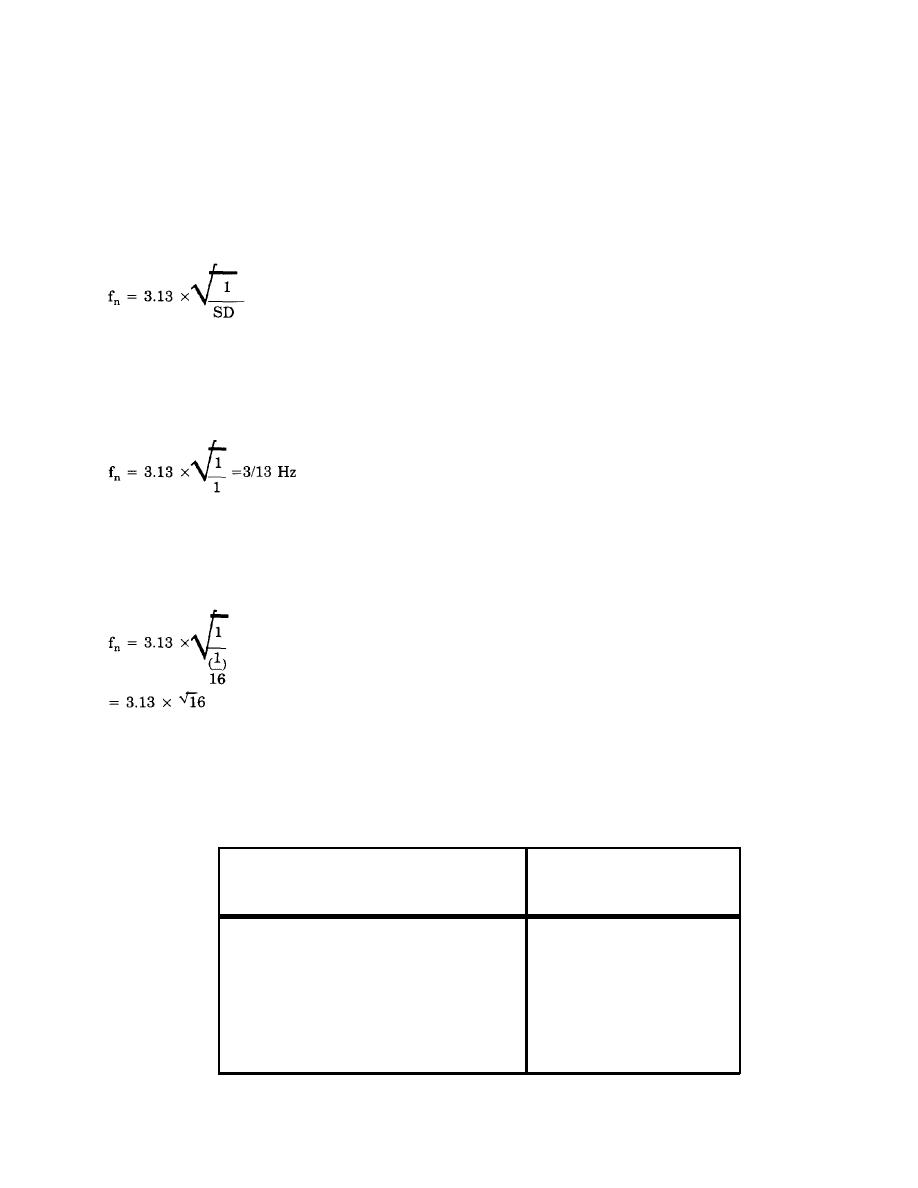

mately from the formula in equation B-17.

but they are more meaningful than such terms as

95 or 98 percent isolation efficiency which are

clearly erroneous when they do not take into

account the mass and stiffness of the floor slab.

(eq B-17)

Vibration control recommendations given in this

where fn is the natural frequency in Hz and S.D.

chapter are based on the application of this table.

is the static deflection of the mount in inches.

(1) Example. Suppose an 1800-rpm motor-

(1) Example, steel spring. Suppose a steel

pump unit is mounted on steel springs having

spring has a static deflection of 1 inch when placed

l-inch static deflection (as in the example under

under one corner of a motor-pump base. The

b(1) above). The driving frequency of the system is

natural frequency of the mount is approximately:

the shaft speed, 1800 rpm or 30 Hz. The natural

frequency of the mount is 3 Hz, and the ratio of

driving frequency to natural frequency is about 10.

(eq B-17)

Table B-3 shows that this would provide a "fair"

(2) Example, rubber pad. Suppose a layer of

to "high" degree of vibration isolation of the motor

3/8-inch-thick ribbed neoprene is used to vibration

pump at 30 Hz. If the pump impeller has 10

isolate high-frequency structure borne noise or

blades, for example, this driving frequency would

vibration. Under load, the pad is compressed

be 300 Hz, and the ratio of driving to natural

enough to have a 1/16-inch static deflection. The

frequencies would be about 100; so the isolator

natural frequency of the mount is approximately:

would clearly give a "high" degree of vibration

isolation for impeller blade frequency.

(2) Caution. The suggestion on vibration isola-

tion offered in the manual are based on experi-

ences with satisfactory installations of conven-

tional electrical and mechanical HVAC equipment

in buildings. The concepts and recommendations

= 3.13 x 4 = 12 Hz

described here may not be suitable for complex

machinery, w i t h unusual vibration modes,

This formula usually has an accuracy to within

mounted on complex isolation systems. For such

about plus or minus 20 percent for material such

problems, assistance should be sought from a

as neoprene-in-shear, ribbed or waffle-pattern neo-

vibration specialist.

prene pads, blocks of compressed glass fiber, and

Table B-3. Suggested Schedule for Estimating Relative Vibration Isolation Effectiveness of a Mounting System.

Ratio of Driving Frequency

Degree of

Vibration

of Source to Natural

Isolation

Frequency of Mount

Amplification

Below 1.4

Negligible

1.4

-

3

Low

3-6

Fair

6

-

10

High

Above 10

B-11

Previous Page

Previous Page