UFC 3-600-02

1 January 2001

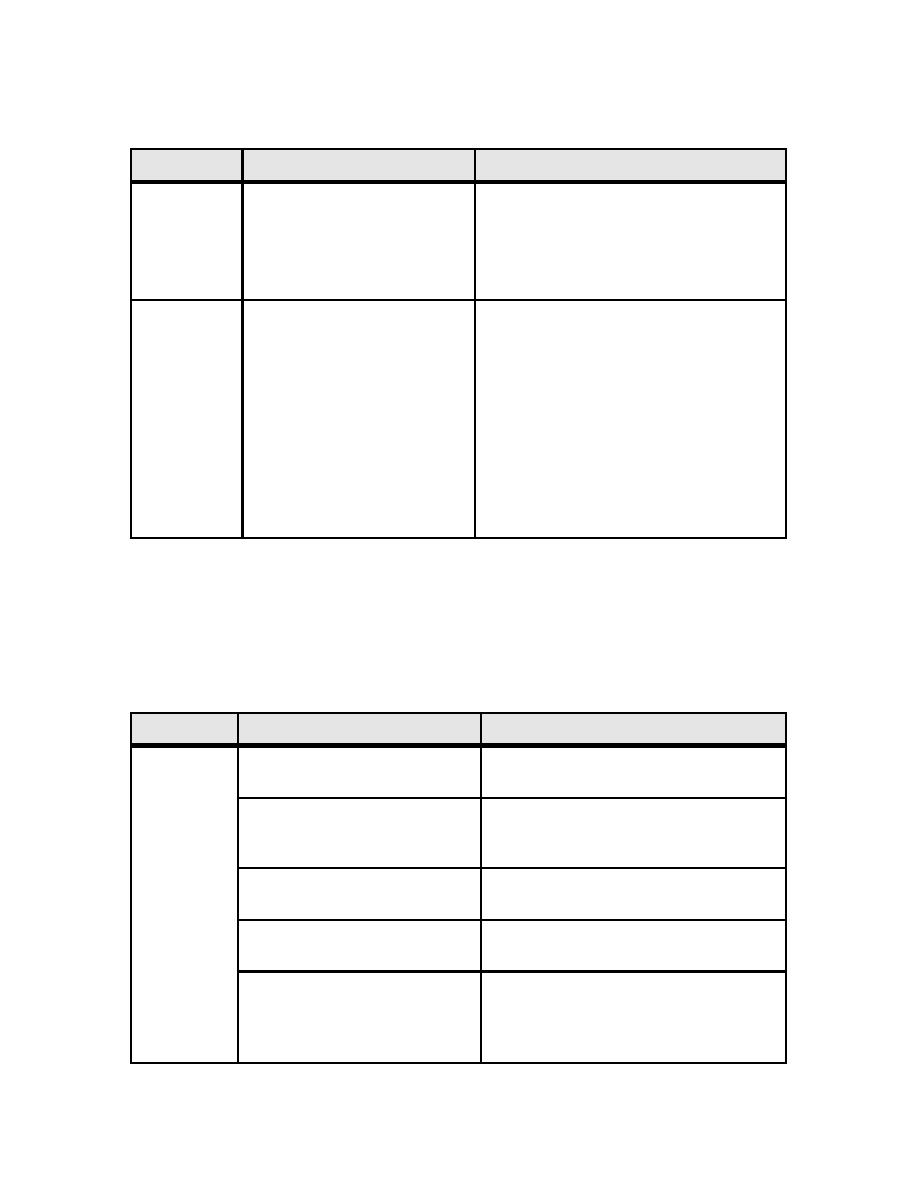

Table 2-7. Water Mist Systems ITM Tasks (Continued)

Component

Task

5-12 Years

1. Storage Vessels

1. Conduct hydrostatic test for

pressure cylinders in accordance

with US Occupational Safety and

Health Administration (OSHA) and

US Department of Transportations

(DOT) standards.

As Part of

Entire System

1. Visually check:

Building

a. Check pipe hangers.

Inspection

b. Check heads for obstruction.

c. Check piping for leaks.

d. Check riser condition.

e. Check nozzle spares.

2. Ensure:

a. Detectors unblocked/uncovered.

b. Panels secured and indicator lamps

functional.

c. Notification appliances in place.

d. Manual stations in place and

unobstructed.

2-2.9

Foam and Foam-Water Systems. Table 2-8 addresses low expansion foam

systems for flammable liquid tanks as covered in NFPA 11. Table 2-9 addresses low

expansion foam spray and sprinkler systems including aqueous film forming foam (AFFF),

as covered in NFPA 16, 16A, and 25. Table 2-10 addresses high expansion foams as

covered in NFPA 11A.

Table 2-8. Low Expansion Foam Systems for Flammable Liquid Tanks ITM Tasks

Component

Tasks

Annual

1. Foam Concentrate

1. Inspect for quality and evidence

of sludge or deterioration.

1. Test to verify operability and

2. Foam Pumps/Proportioners

proper proportioning.

2. Flush pumps after operation.

3. System Actuators

1. Verify all manual and automatic

actuation functions.

1. Inspect and clean if necessary.

4. Foam Concentrate

Strainers

1. Ensure discharge devices are

5. Distribution/Discharge

free of damage.

2. Inspect pipe and hanger to verify

support and pitch.

Table 2-8. Low Expansion Foam Systems for Flammable Liquid Tanks ITM

2-13

Previous Page

Previous Page