UFC 3-600-02

1 January 2001

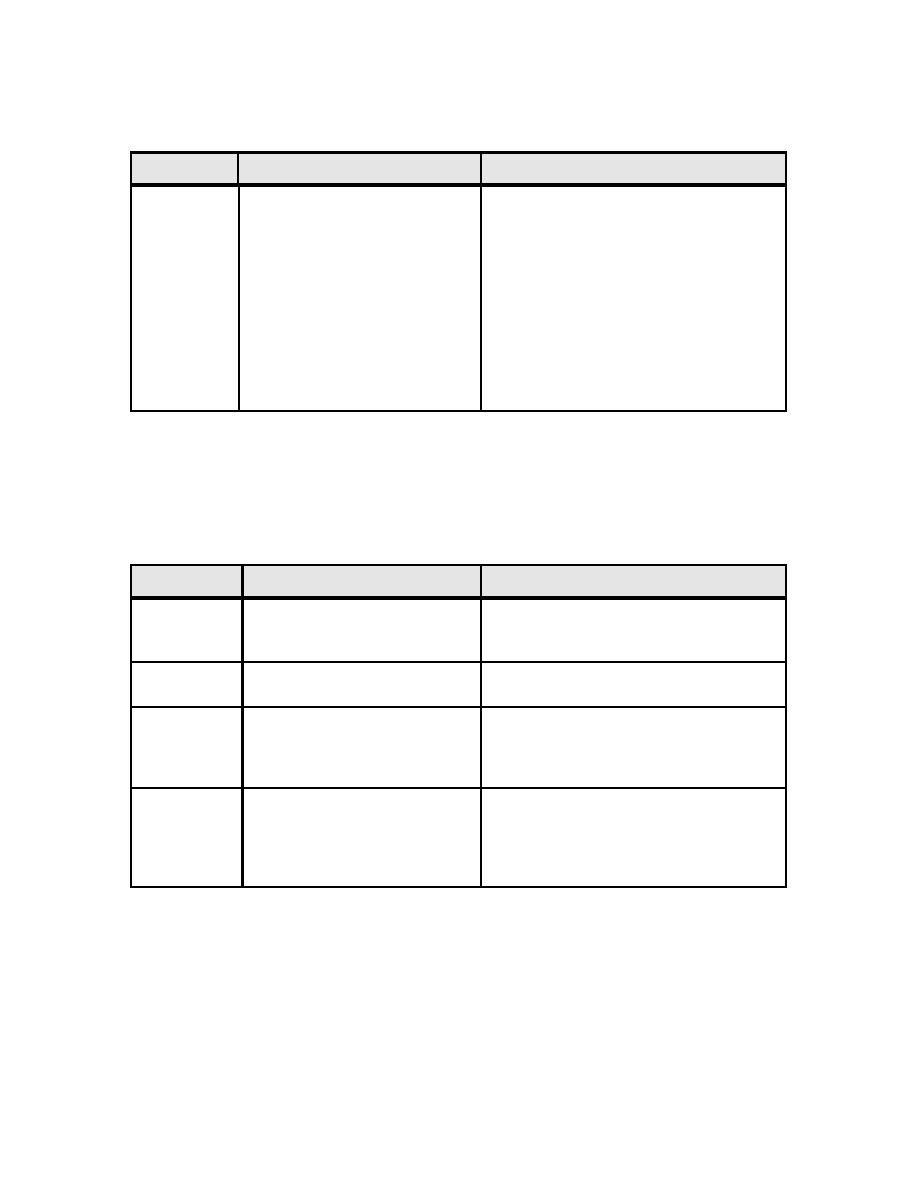

Table 2-10. High Expansion Foam Systems ITM Tasks (Continued)

Component

Tasks

As Part of

Entire System

1. Visually Check:

Building

a. Pipe hangers.

Inspection

b. Heads for obstruction.

c. Piping for leaks.

d. Riser condition.

2. Ensure:

a. Detectors unblocked/uncovered.

b. Panels secured and indicator

lamps functional.

c. Notification appliances in place.

d. Manual stations in place and

unobstructed.

2-2.10

Standpipe Systems. Detection devices for actuation are addressed in

paragraph 2-2.2. Technical guidance on the tasks is contained in NFPA 14 and 25.

Table 2-11. Standpipe Systems ITM Tasks

Component

Tasks

Semi-

1. Hose Connection and

1. Inspect for damage, leaking,

Annual

Pressure Reducing

missing caps, and obstruction.

Valves

2 Years

1. Piping

1. Inspect for damage and pipe

supports.

5 Years

1. Standpipe

1. Conduct flow test to verify flow

capacity.

2. Hydrostatic test to ensure

integrity.

As Part of

Entire System

1. Visually check:

Building

a. Pipe hangers.

Inspection

b. Connections for obstruction.

c. Piping for leaks.

d. Riser condition.

2-16

Previous Page

Previous Page