UFC 3-600-02

1 January 2001

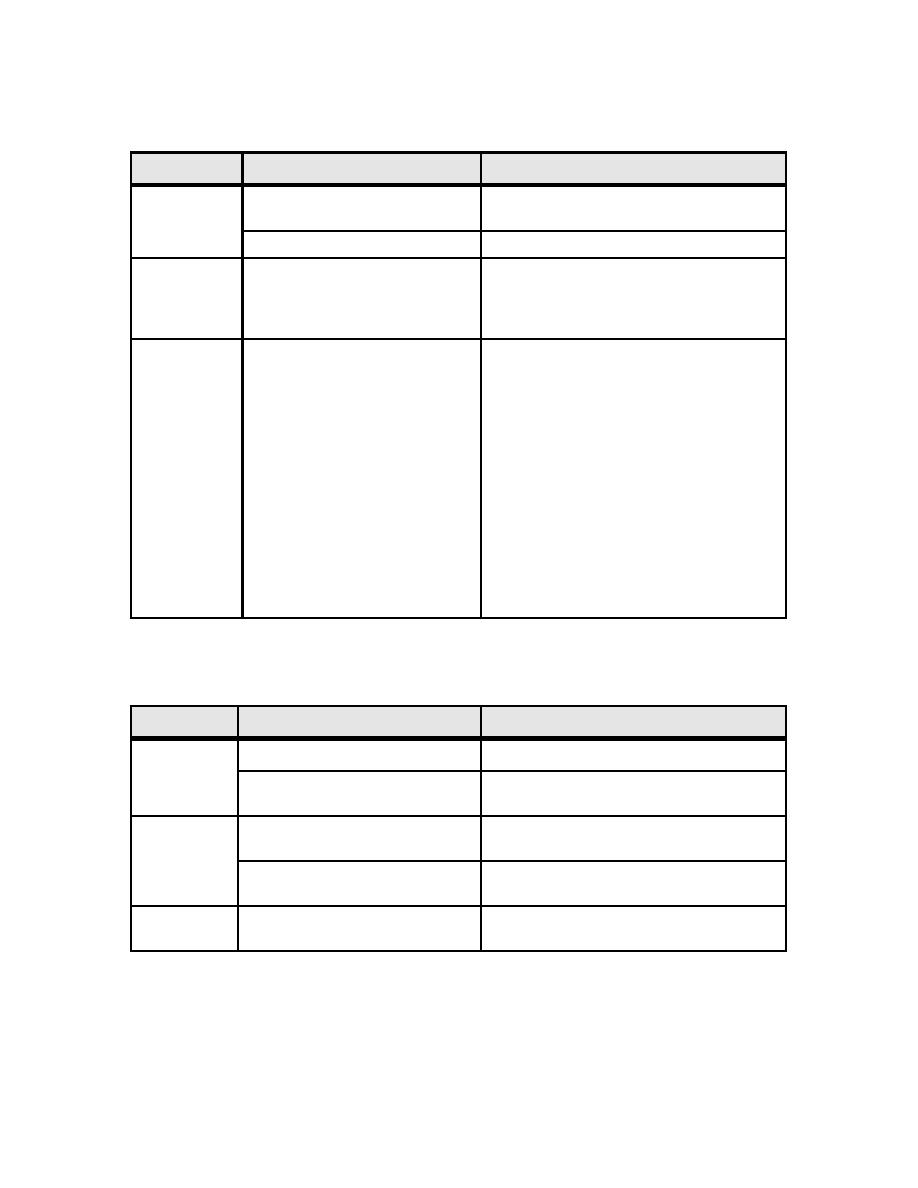

Table 2-9. Foam Spray and Sprinkler Systems ITM Tasks (Continued)

Component

Tasks

5 Years

1. Balancing Valve

1. Flush to prevent concentrate build-

up on diaphragm.

2. Strainers (water supply)

1. Inspect and clean if necessary.

10 Years

1. Foam Concentrate Tank

1. Drain, flush and perform internal

inspection for corrosion. If

pressure vessel, perform

hydrostatic test.

As Part of

Entire System

1. Visually check:

Building

a. Pipe hangers.

Inspection

b. Heads for obstruction.

c. Piping for leaks.

d. Riser condition.

2. Ensure:

a. Detectors

unblocked/uncovered.

b. Panels secured and indicator

lamps functional.

c. Notification appliances in

place.

d. Manual stations in place and

unobstructed.

3. Check sprinkler spares.

Table 2-10. High Expansion Foam Systems ITM Tasks

Component

Tasks

Annual

1. Foam Concentrate

1. Inspect to verify adequate supply.

2. Foam Generator

1. Inspect to verify condition and

proper valve alignment.

2 Years

1. Foam Generator

1. Conduct discharge test to verify

operability.

2. Actuators

1. Verify all manual and automatic

actuators function.

After

1. Strainers

1. Inspect and clean after system

Activation

actuation.

2-15

Previous Page

Previous Page