UFC 4-730-10

15 June 2006

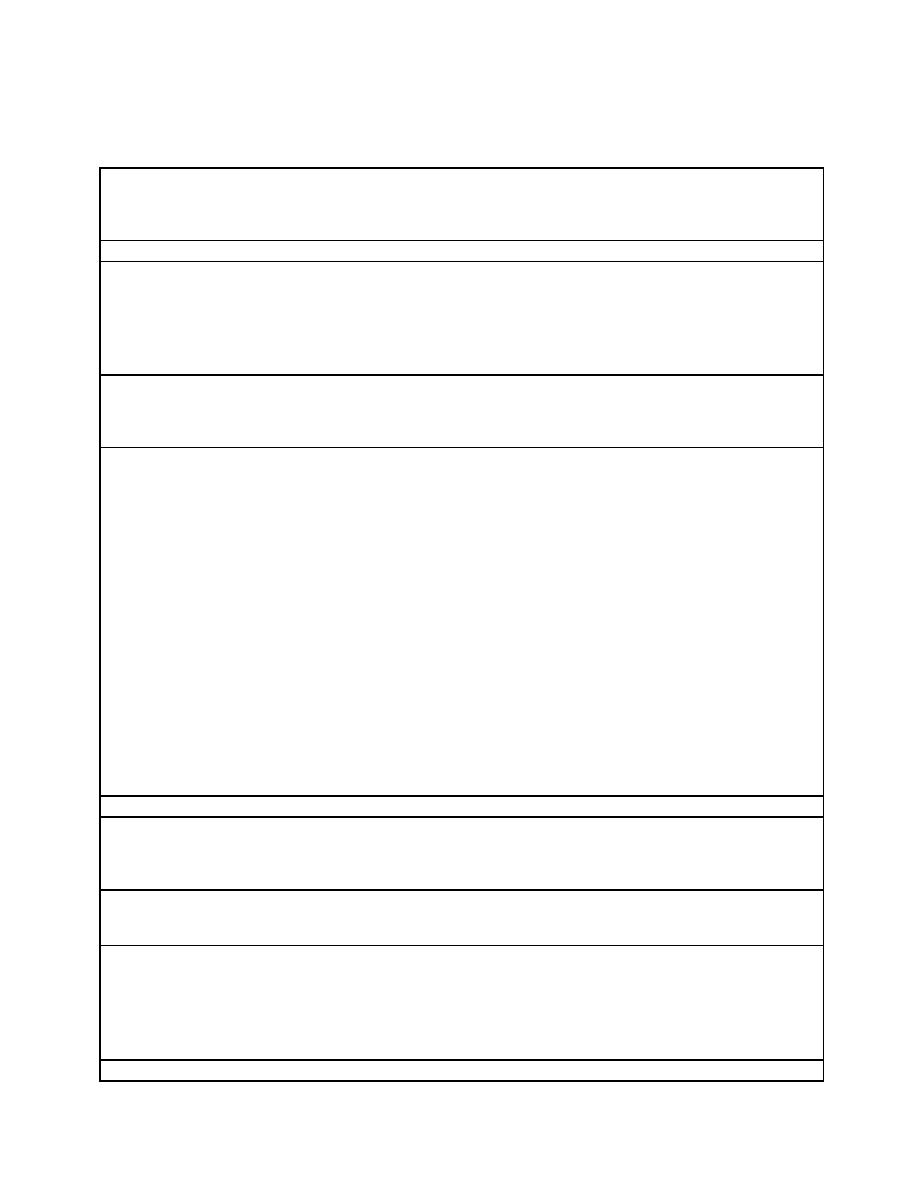

TABLE 4-12.0. VEHICLE MAINTENANCE BAY

This space is mainly used to service and repair firefighting vehicles, if required by Installation

Description/

mission requirements. At times, this bay may be used as an additional Apparatus Bay as well.

Usage

The bay is sized to accommodate the largest vehicle and the equipment required to service it.

Similar to the Apparatus Bay, the Vehicle Maintenance Bay should be a drive-through.

4.26 m (14 ft.) minimum.

Min. Ceiling Ht.

Walls. CMU. Provide epoxy paints on all wall surfaces.

Floor. Provide a sealed concrete surface. A non-skid, low-maintenance traffic coating may

also be acceptable.

Ceiling. Ceiling not required; however, consider finishing exposed structure. Consider

coordinating mechanical, electrical, and plumbing components. Note that none of the ceiling

components can be located below minimum ceiling height.

Provide minimum 75-mm- (3-in.-) diameter water service with 62-mm- (2.5 in) diameter

Plumbing

National Standard Threads ball valved outlet to each vehicle. Provide standard hot and cold

water hose bibb. Provide floor trench drains parallel to the centerline of each vehicle. Trench

drain should connect to an approved oil/water separator prior to discharge to the sanitary sewer.

The Vehicle Maintenance Bay is typically heated. Maintain 20 C (68 F) minimum temperature

HVAC

except in areas with very mild winter conditions. Determine exceptions on a case-by-case basis

based on climatic conditions.

The Services will not air condition the Vehicle Maintenance Bay except through exceptions. :

For the Army, refer to TI-800-1, Design Criteria for the appropriate exceptions. The Air

Force will determine on a case-by-case basis based on climatic conditions how to condition the

Apparatus Bay. In addition to considering climatic conditions, consider the energy costs and

sustainability impacts.

Provide a Fire Apparatus Vehicle Exhaust Removal System (FAVERS) in compliance with

NFPA 1500 to eliminate 100% of vehicle exhaust emissions. A direct vent system that

evacuates vehicle exhaust directly to the outside is the preferred FAVERS. Make-up air should

be distributed so as to minimize drafts and be introduced above apparatus level since diesel

exhaust is heavier than air. In this way, the make-up air flow downward will assist in pushing

the exhaust fumes out the Apparatus bay doors when open.

Provide compressed air system on self-retracting lines at each vehicle bay. Consider providing

floor radiant heating element at each door in colder climates to prevent the door from freezing

to the pavement.

Provide Fire Protection System per Paragraph 3-6.3.

Fire Protection

Provide outlets per code. Locate all outlets at 900 mm (36 in.) above finished floor. Provide

Power

self-retracting electric drop cords between vehicles. Provide backup power sized to provide full

unobstructed operation capability of the Apparatus Bays and Vehicle Maintenance Bay.

Provide power to each retractable door.

Provide Lighting System per Paragraph 3-6.4.1. Provide energy efficient lighting with instant-

Lighting

start feature. Provide doors with signaling system indicating fully raised doors. A red/green

indicator should be located on the driver's side at 1800 mm (6 ft.) above finished floor.

CCTV. Provide interior and exterior and cameras located to provide adequate coverage.

Communication

CATV/Internal Video. None required.

PA/Audio. Provide speakers and horns with visual element.

Telephone. Provide one line with internal two-way communication.

Data. Provide data drops as required by equipment.

Security. None required.

None required.

Casework

4-14

Previous Page

Previous Page