Page 44

DG 1110-3-124

August 1976

Operational

Clearances

greater maintenance. Floors should be nonslip. Low

ing machinery) in woodworking according to

type

windows are not desirable but windows may be provided

of activity in progress. ]

Width/length ratio

above door head height. All glazing should be wire glass or

plastic.

of work area:

minimum 1/1, maximum

1/2

Minimum width of

general work area:

30

feet

d.

RECOMMENDED

SPACE

ALLOCATIONS

Minimum ceiling height:

12

feet

For a center of 20,650 square feet, approximately 7,225

e. RELATED SPACES

square feet should be allocated for woodworking.

The woodworking shop should be located in an area of

General Work Area

3,025

square

feet

the building which isolates noise. A supervisor's station

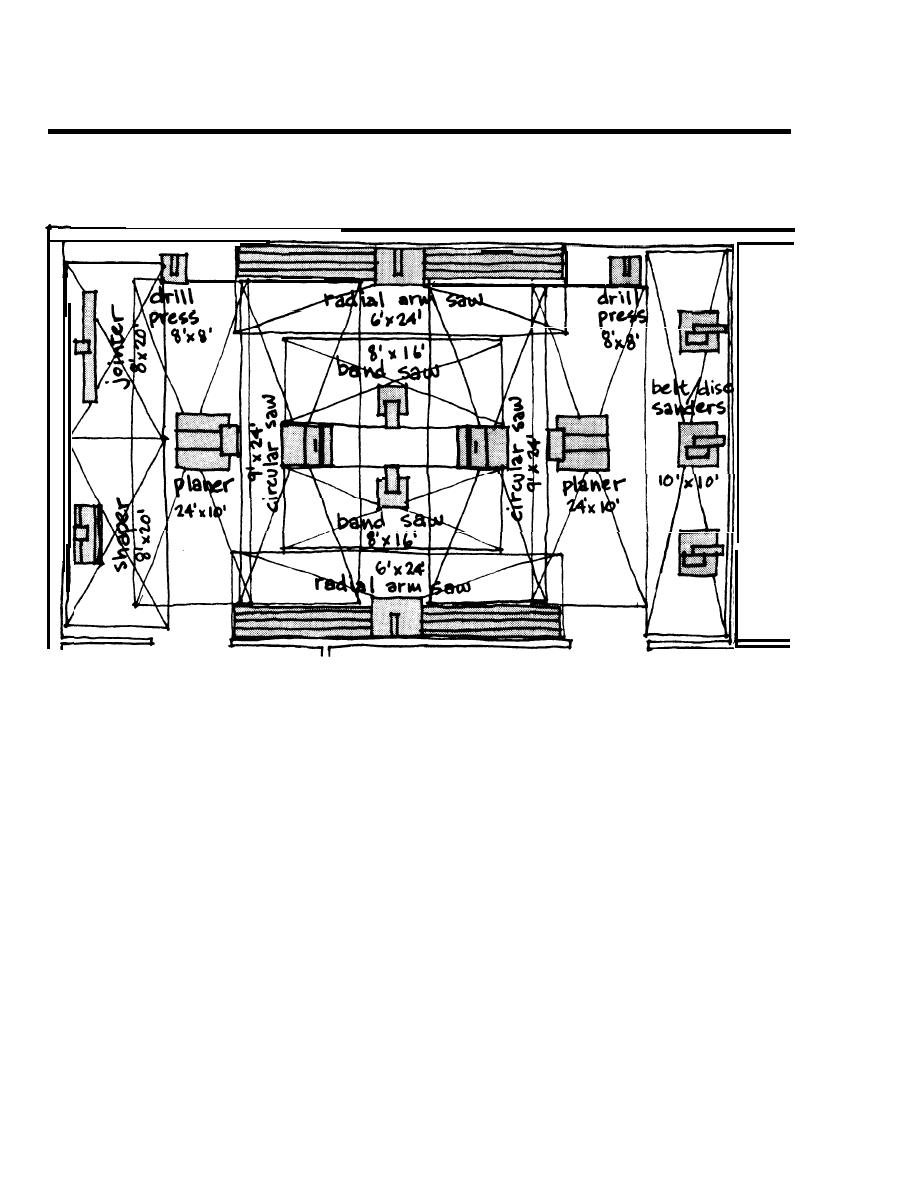

Power Equipment Area

2,000

square

feet

should be near or part of office and tool issue room. The

Lumber Storage

500

square

feet

service and material receiving entrance should be under

Project Storage

600

square

feet

staff supervision. Convenient access is needed to the tech-

Finish Room

400

square

feet

nical reference Iibrary. Wash-up areas and lockers for work

Tool Issue Room and

clothes should be provided near the shop entrance.

Supervisor's Station

300 square feet

Covered Exterior Work Area

400 square feet*

* Amount indicates half of actual exterior area provided since

f. FURNISHINGS EQUIPMENT

covered exterior Work area is programmed as half of interior

.

building space.

(1) The National Safety Council and Army Safety Direc-

NOTE: [For safe working conditions an allowance of 75

tors urge that special precautions be taken in all wood-

to 125 square feet per person is required (includ -

working areas to prevent accidents to participants. All

Previous Page

Previous Page