UFC 3-460-03

21 JANUARY 2003

3. Remove small test sections of insulation and check

ٱ

roof deck for corrosion and holes near the edge of the

insulated area.

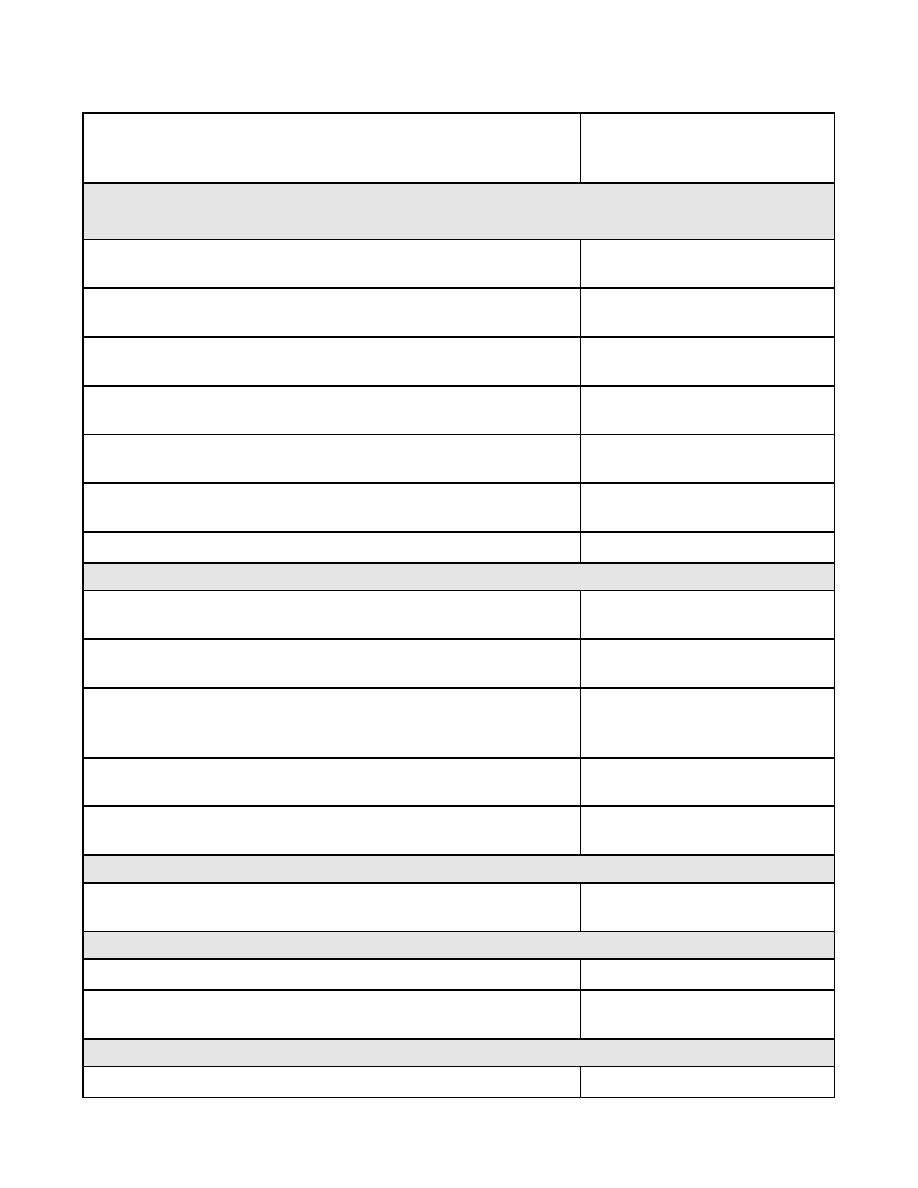

ROOF APPURTENANCES

Sample Hatch

1. Inspect condition and functioning of sample hatch

ٱ

cover.

2. On tanks governed by Air Quality Monitoring District

ٱ

rules, check the condition of the inside hatch cover seal.

3. Check thief and hatch gauge cover for corrosion and

ٱ

plugging.

4. Where a sample hatch is used to reel gauge stock level,

ٱ

check for marker and tab stating hold-off distance.

5. Check reinforcing pad where sample hatch pipe

ٱ

penetrates the roof deck.

6. On floating roof sample hatch and recoil systems,

ٱ

inspect operation of recoil reel and condition of rope.

ٱ

7. Test system operation.

Gauge Well

1. Inspect visible portion of the gauge well for thinning,

ٱ

size of slots, and cover condition.

2. Check for hold-off distance marker and tab with hold-

ٱ

off distance (legible).

3. On floating roofs, inspect condition of roof guide for

ٱ

gauge well, particularly the condition of the rollers for

grooving.

4. If accessible, check the distance from the gauge well

ٱ

pipe to the tank shell at different levels.

5. If tank has a gauge well washer, check valve for leaks

ٱ

and for presence of a bull plug or blind flange.

Fixed Roof Scaffold Support

Inspect scaffold support for corrosion, wear, and

ٱ

structural soundness.

Autogauge Inspection Hatch and Guides (Fixed Roof)

ٱ

1. Check the hatch for corrosion and missing bolts.

2. Look for wire anchor corrosion on the tape guide and

ٱ

float guide.

Autogauge Float Well Cover

ٱ

1. Inspect for corrosion.

152

Previous Page

Previous Page