UFC 3-460-03

21 JANUARY 2003

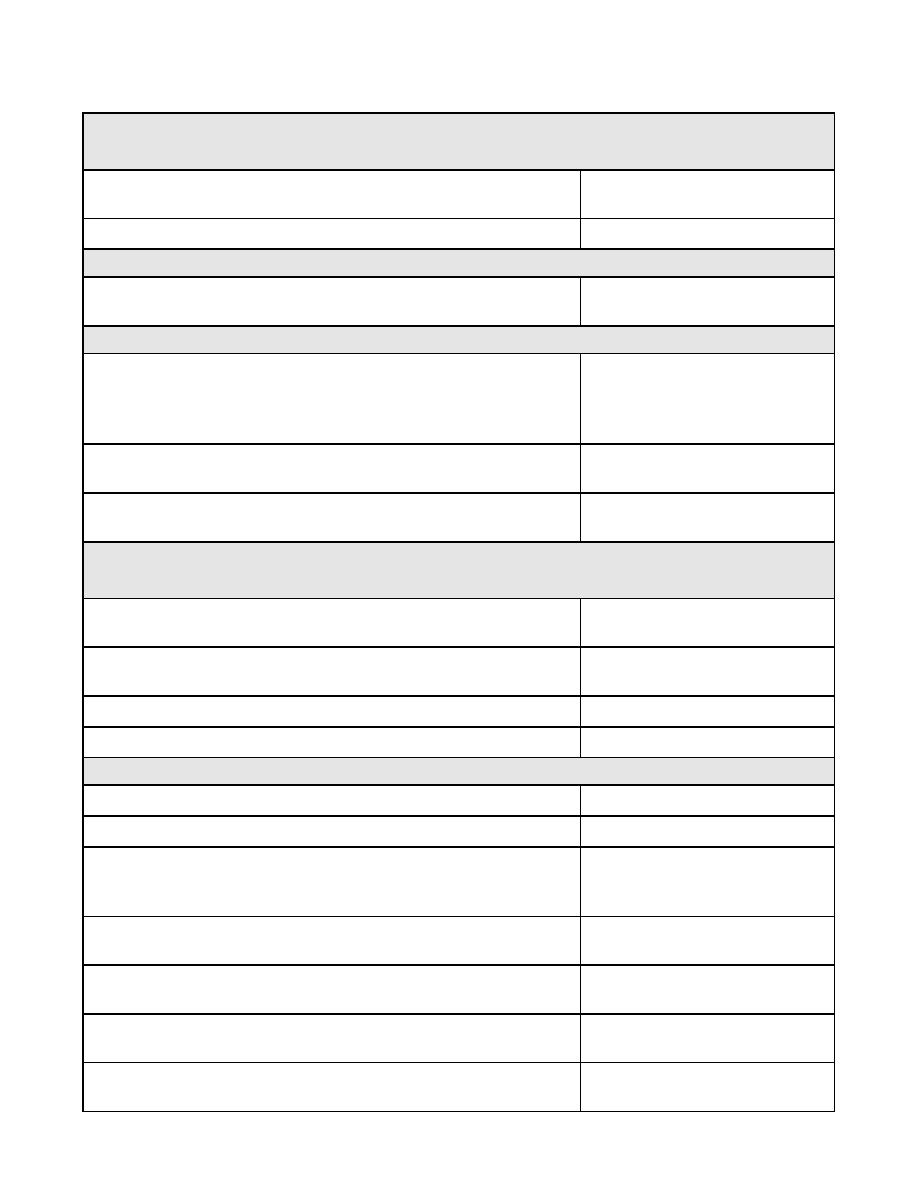

SHELLS

External Visual Inspection

1. Visually inspect for paint failure, pitting, and

ٱ

corrosion.

ٱ

2. Inspect the bottom-to-foundation seal (if applicable)

Internal (Floating Roof Tank)

Visually inspect for grooving, corrosion, pitting, and

ٱ

coating failure.

Wind Girder (Floating Roof Tank)

1. Inspect wind girder and handrail for corrosion damage

(paint failure, pitting, and corrosion product buildup -

ٱ

especially where it occurs at tack-welded junctions) and

broken welds.

2. Check support welds to the shell for pitting, especially

ٱ

on shell plates.

3. Note whether supports have reinforcing pads welded to

ٱ

the shell.

SHELL APPURTENANCES

Manways and Nozzles

1. Inspect for cracks or leaks on weld joints at nozzles,

ٱ

manways, and reinforcing plates.

2. Inspect for shell plate dimpling around nozzles caused

ٱ

by excessive pipe deflection.

ٱ

3. Inspect for flange leaks and leaks around bolts.

ٱ

4. Inspect insulation seal around manways and nozzles.

Tank Piping Manifolds

ٱ

1. Inspect manifold piping, flanges, and valves for leaks.

ٱ

2. Inspect firefighting system components.

3. Check for anchored piping that would be hazardous to

ٱ

the tank shell or bottom connections during earth

movement.

4. Check for adequate thermal pressure relief of piping to

ٱ

the tank.

5. Check regulator operation for tanks with purge gas

ٱ

systems.

6. Check sample connections for leaks and proper valve

ٱ

operation.

7. Check temperature indicators for damage and test their

ٱ

accuracy.

150

Previous Page

Previous Page