UFC 3-460-03

21 JANUARY 2003

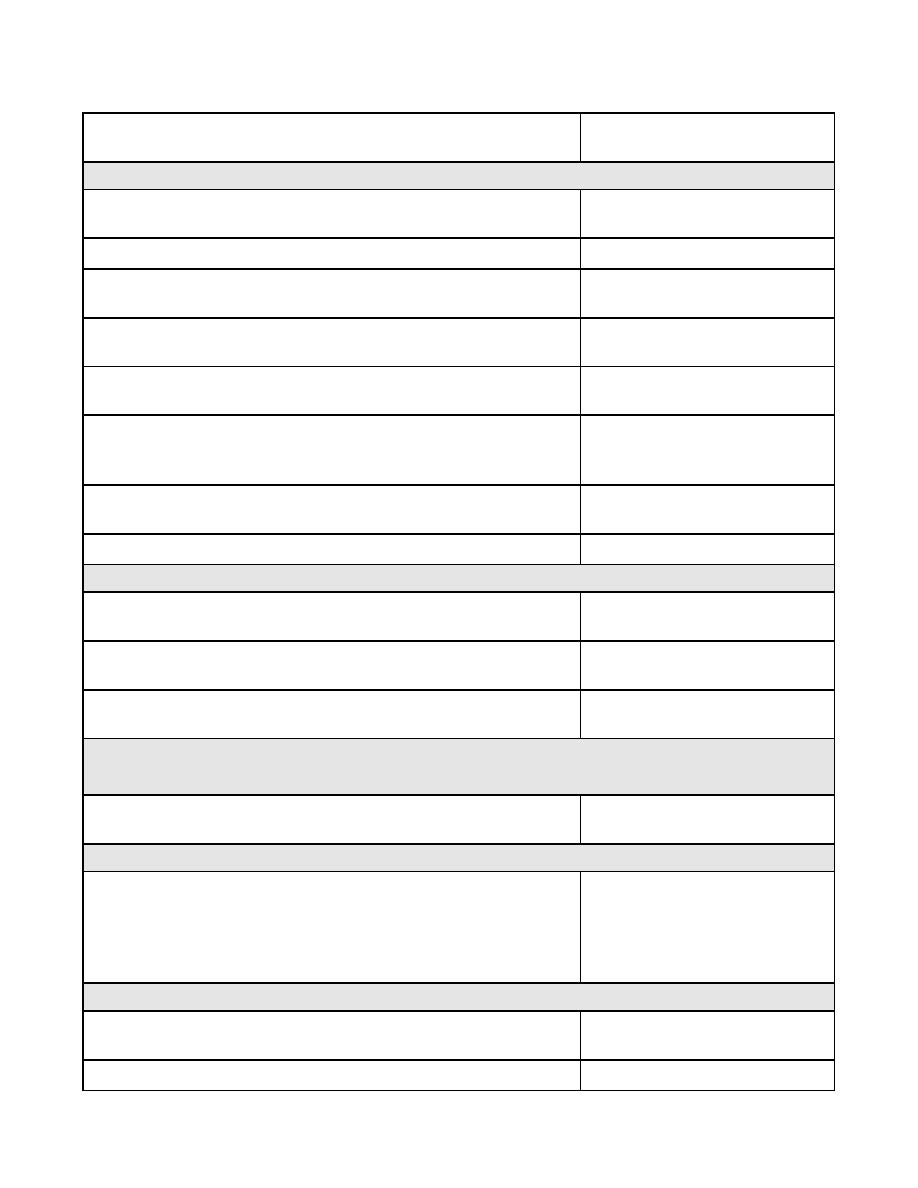

8. Check welds on shell-mounted davit clips above

ٱ

152-mm (6-in) and larger valves.

Autogauge System

1. Inspect autogauge tape guide and lower sheave

ٱ

housing (floating swings) for leaks.

ٱ

2. Inspect autogauge head for damage.

3. Bump the checker on the autogauge head for proper

ٱ

movement of the tape.

4. Ask the operator if the tape tends to hang up during

ٱ

tank roof movement (floating roof tanks).

5. Compare actual product level to the autogauge reading

ٱ

(maximum allowable variation is 51 mm [2 in]).

6. On floating roof tanks, when the roof is in the lowest

ٱ

position, check that no more than 0.6 m (2 ft) of tape are

exposed at the end of the tape guide.

7. Inspect the condition of board and legibility of board-

ٱ

type autogauges.

ٱ

8. Test freedom of movement of marker and float.

Shell-Mounted Sample Station

1. Inspect sample lines for valve function and line

ٱ

plugging, including return-to-tank line drain.

2. Check circulation pump for leaks and operating

ٱ

problems.

3. Test bracing and supports for sample lines and

ٱ

equipment.

ROOFS

Deck Plate External Corrosion

Inspect roof deck for paint failure, holes, pitting, and

corrosion product.

Roof Deck Drainage

Look for evidence of standing water. (Significant sagging

of fixed-roof deck shows potential rafter failure. Large

ٱ

standing water areas on a floating roof show inadequate

drainage design, or, if to one side, a non-level roof with

possible leaking pontoons.)

Roof Insulation

1. Inspect for cracks or leaks in the insulation weather

ٱ

coat where runoff water could penetrate the insulation.

ٱ

2. Inspect for wet insulation under the weather coat.

151

Previous Page

Previous Page